Product Details

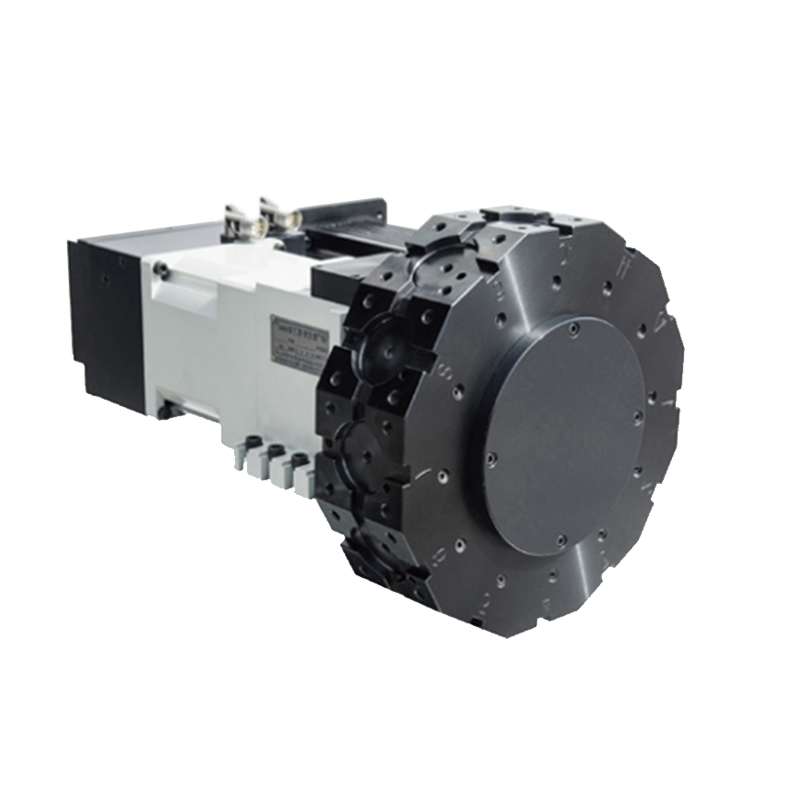

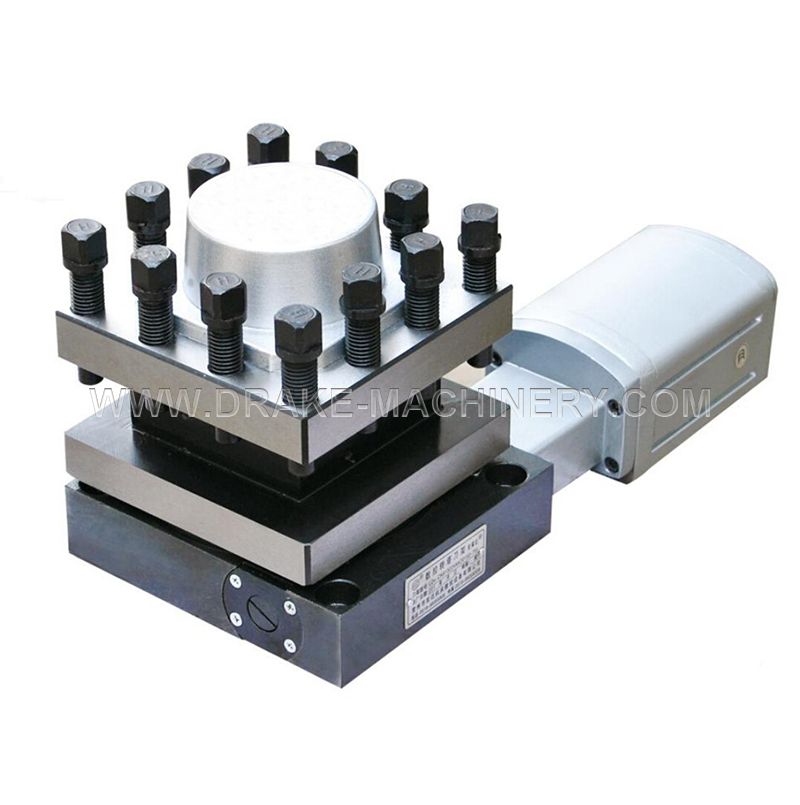

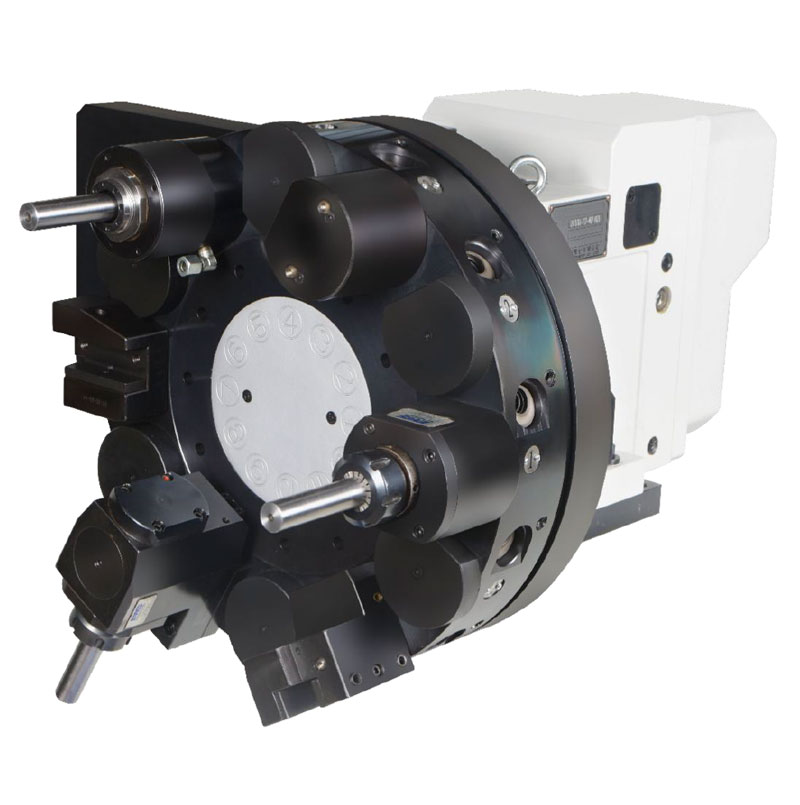

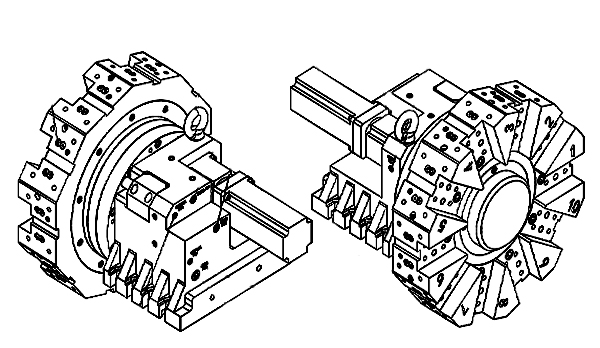

LD4 series vertical NC turret adopts the working principle of worm wheel and worm for driving, face gear coupling as fine indexing mechanism, big screw for clamping,sending signals with Hall unit. It features fast change tools, high repeatability accuracy, high stiffness. It is a popular product for economic NC lathe.

1. Confirm various parameters when choosing models of turret. Choose the number of stations according to quantity of part procedure and complicacy.

2. Choose tool specifications according to model of machine tool and cutting force. Choose the front type or rear type tool turret according to the cutting directions of the machine tool.

3. After the mounting of boring cutter seat of horizontal turret, Self-bore the inner hole according to the size of boring bar and make a corresponding mark. The tool should be fixed in the former position in the later mounting.

4. The distance tool reaching out of upper housing distance is usually not more than 2/3 upper housing size. Please note when placing an order,if more than the limit.

5. Touch by hand or other things is forbidden when turret is running to avoid injury or damage.

6. If customers have any special requirements or changes in parameters, please offer some data and contact with our company.

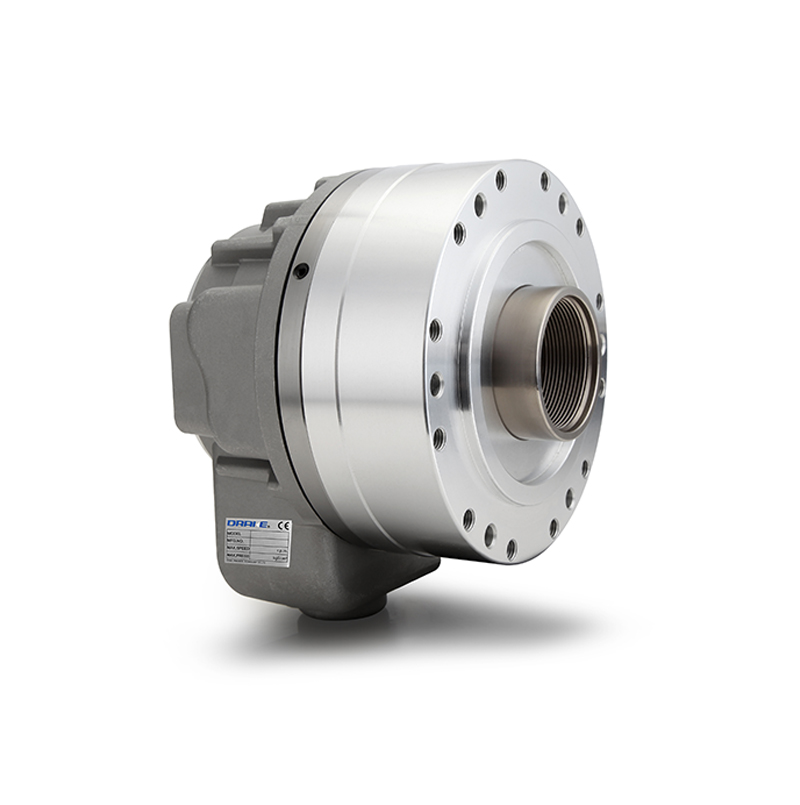

Drake is a leading enterprise with 15+ years of factory experience, specializing in machine tool accessories and offering OEM & ODM services. We cooperate with over 60 countries and provide one-stop purchasing solutions for for Power Chuck, Collet Chuck, Turret, Tool Holder, Rotary Cylinder, Laser Chuck, Tool magazine, and more. Our strict adherence to international quality standards and comprehensive product range ensures tailored processing solutions for diverse customer needs.

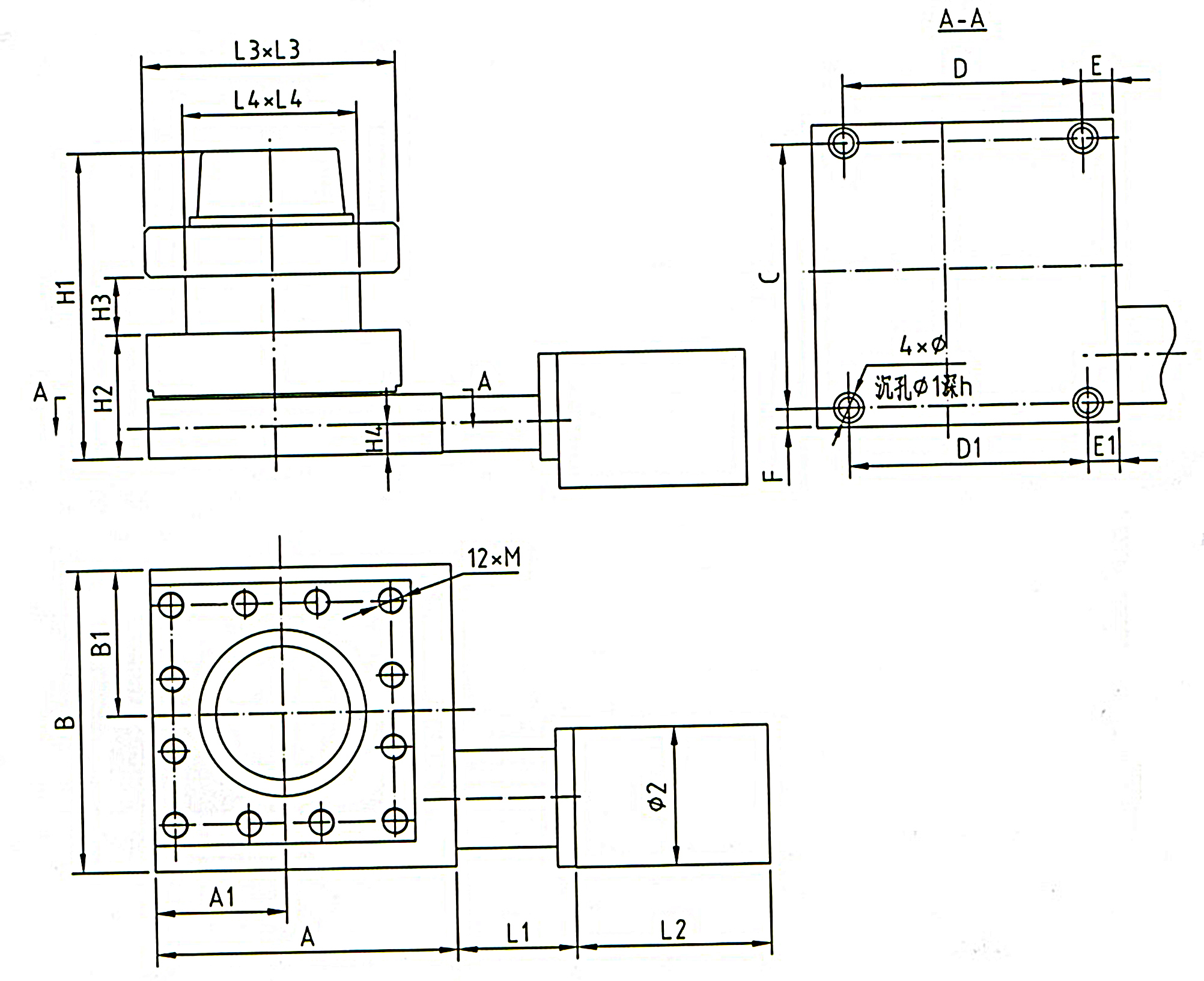

Product Size

Product Parameters

| Model/Data | Center height (mm) | Motor power(W) | Max.tangential torque(N·m) | Repeatability accuracy(") | Time of changing tool and lock(s) | ||

| 90º | 180º | 270º | |||||

| LD4CK0610 | 40 | 40 | 100 | ±2 | 1 | 1.4 | 1.8 |

| LD4CK0620 | 48 | 50 | 150 | ±2 | 1.2 | 1.6 | 2 |

| LD4CK0625 | 51 | 90 | 300 | ±2 | 1.7 | 2.2 | 2.7 |

| LD4CK6125 | 57 | 90 | 400 | ±2 | 1.9 | 2.4 | 2.9 |

| LD4CK6132 | 70 | 120 | 500 | ±2 | 2 | 2.5 | 3 |

| LD4CK6136 | 77 | 120 | 500 | ±2 | 2 | 2.5 | 3 |

| LD4CK6140 | 81 | 120 | 600 | ±2 | 2 | 2.5 | 3 |

| LD4CK6150 | 121 | 120 | 600 | ±2 | 2 | 2.5 | 3 |

| LD4CK6163 | 120 | 180 | 800 | ±2 | 2.5 | 3.2 | 3.9 |

| Model/Dim | H1 | H2 | H3 | H4 | L1 | L2 | L3 | L4 | A | A1 | B | B1 |

| LD4CK0610 | 86 | 40 | 15 | 11 | 57.5 | 86 | 70 | 50 | 70 | 35 | 87 | 36 |

| LD4CK0620 | 116 | 48 | 19 | 16 | 58 | 100 | 80 | 56 | 80 | 40 | 110 | 55 |

| LD4CK0625 | 128 | 51 | 22 | 16 | 86 | 118 | 110 | 80 | 120 | 55 | 126 | 56 |

| LD4CK6125 | 162 | 57 | 35 | 16.5 | 110 | 118 | 136 | 96 | 136 | 68 | 148 | 68 |

| LD4CK6132 | 187 | 70 | 40 | 21 | 76 | 127 | 152 | 104 | 161 | 76 | 171 | 76 |

| LD4CK6136 | 194 | 77 | 33 | 21 | 76 | 127 | 152 | 104 | 161 | 76 | 171 | 76 |

| LD4CK6140 | 202 | 81 | 40 | 23 | 76 | 127 | 162 | 112 | 192 | 81 | 192 | 105 |

| LD4CK6150 | 242 | 121 | 40 | 47 | 76 | 127 | 162 | 112 | 192 | 81 | 192 | 105 |

| LD4CK6163 | 253 | 120 | 51 | 40 | 110 | 132 | 200 | 124 | 200 | 100 | 200 | 100 |

| Dim Model | C | D | D1 | E | E1 | F | φ | φ1 | φ2 | h | M |

| LD4CK0610 | 74 | 57 | 50 | 6.5 | 10 | 6.5 | φ7 | φ11 | φ68 | 6.5 | M6 |

| LD4CK0620 | 94 | 64 | 52 | 8 | 13 | 8 | φ9 | φ14 | φ78 | 9 | M8 |

| LD4CK0625 | 110 | 90 | 80 | 15 | 20 | 8 | φ9 | φ14 | φ88 | 9 | M10 |

| LD4CK6125 | 126 | 108 | 108 | 14 | 14 | 11 | φ11 | φ17 | φ88 | 11 | M12 |

| LD4CK6132 | 146 | 126 | 126 | 23 | 23 | 12 | φ13 | φ19 | φ88 | 13 | M16 |

| LD4CK6136 | 146 | 126 | 126 | 23 | 23 | 12 | φ13 | φ19 | φ88 | 13 | M16 |

| LD4CK6140 | 168 | 152 | 152 | 20 | 20 | 12 | φ13 | φ19 | φ88 | 13 | M16 |

| LD4CK6150 | 168 | 152 | 152 | 20 | 20 | 12 | φ13 | φ19 | φ88 | 13 | M16 |

| LD4CK6163 | 177 | 150 | 130 | 25 | 35 | 11.5 | φ13 | φ19 | φ98 | 13 | M16 |

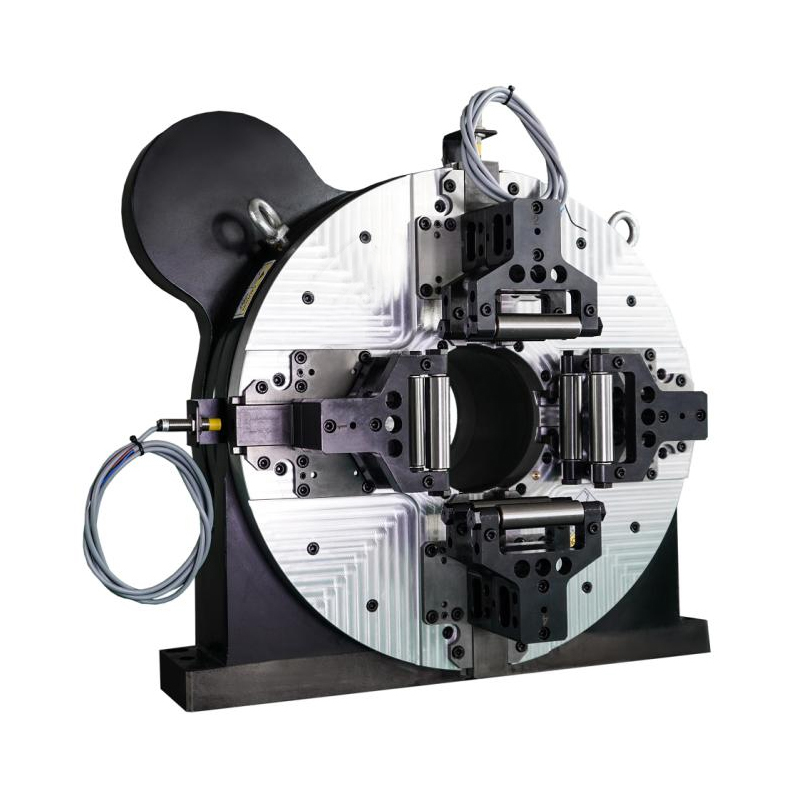

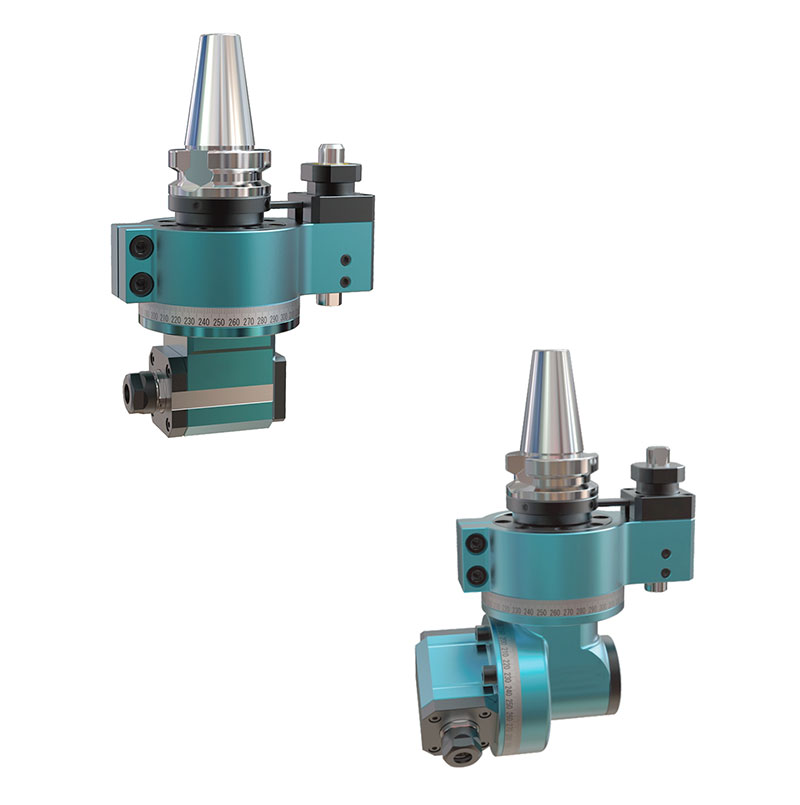

The 4 station automatic tool turret is widely used in CNC machining for efficient tool changes, enhancing productivity. A 4-station tool turret setup enables quick rotation and switching of tools, which is especially valuable in high-speed operations. For machines like a CNC vertical turret lathe holder, having a driven turret tool option can further increase flexibility by allowing powered tooling operations. In such setups, the 4 station tooling configuration is designed to optimize space and time, catering to the demands of modern manufacturing.