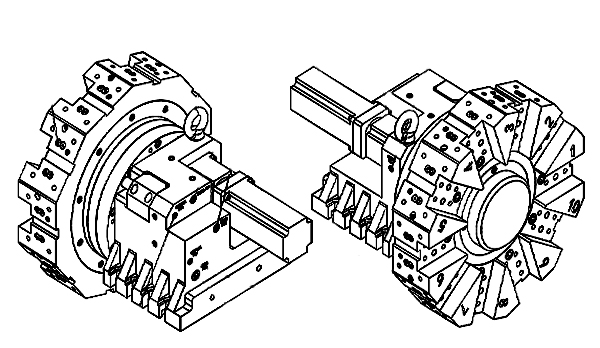

Product Details

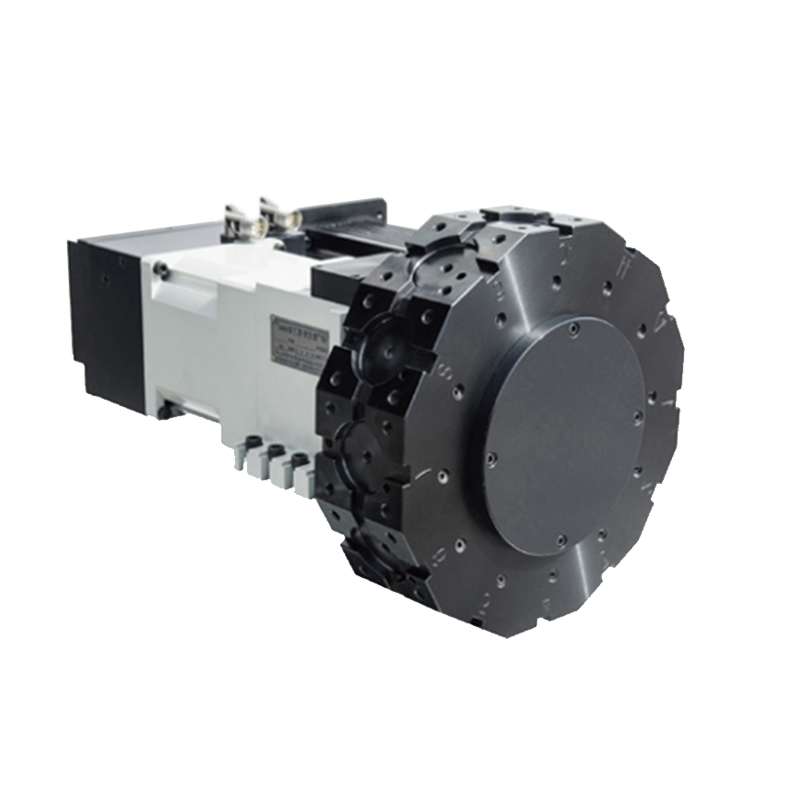

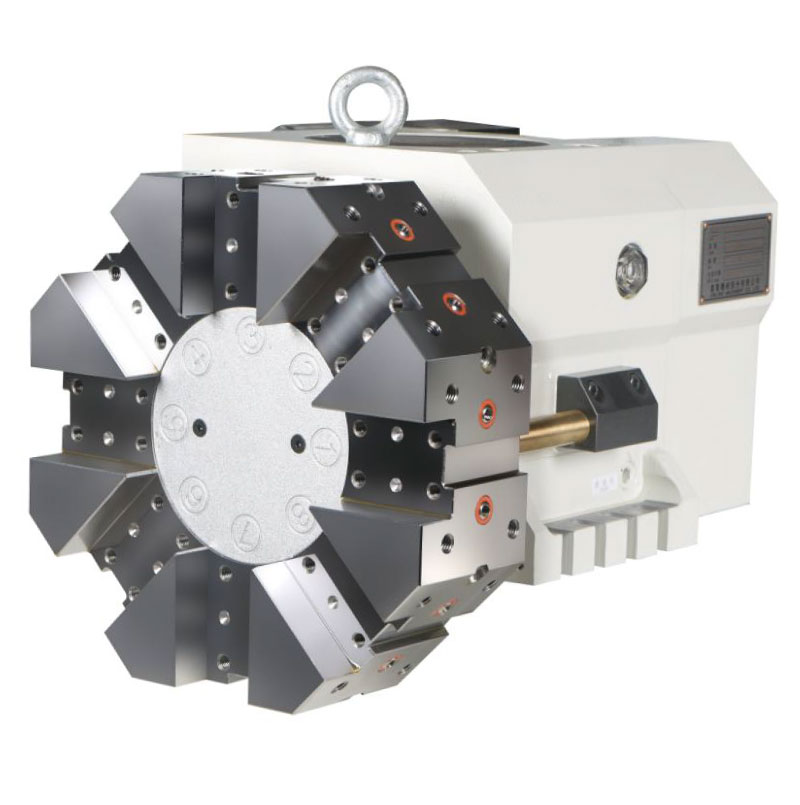

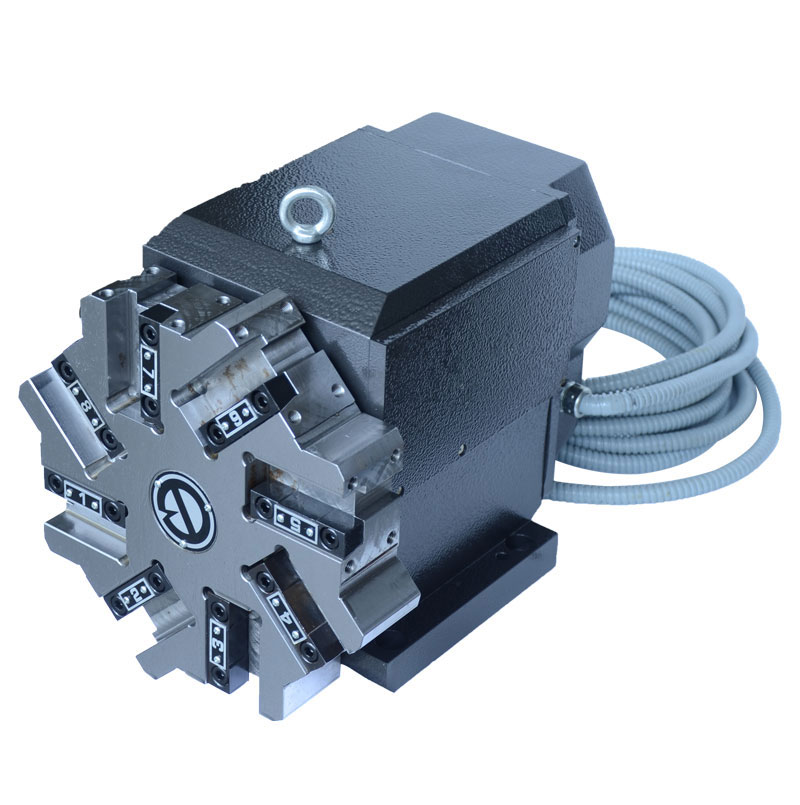

Axial servo power tooling turrets are advanced components in CNC (Computer Numerical Control) machining centers, providing enhanced flexibility, precision, and efficiency. These turrets, driven by servo motors, allow for the automated and precise positioning of multiple tools, enabling complex machining operations without the need for manual tool changes.

1.Taking D series servo turret as the platform, external power module is added to compose SLTAserviesaxial power tooling servo, which has reasonably compact layout

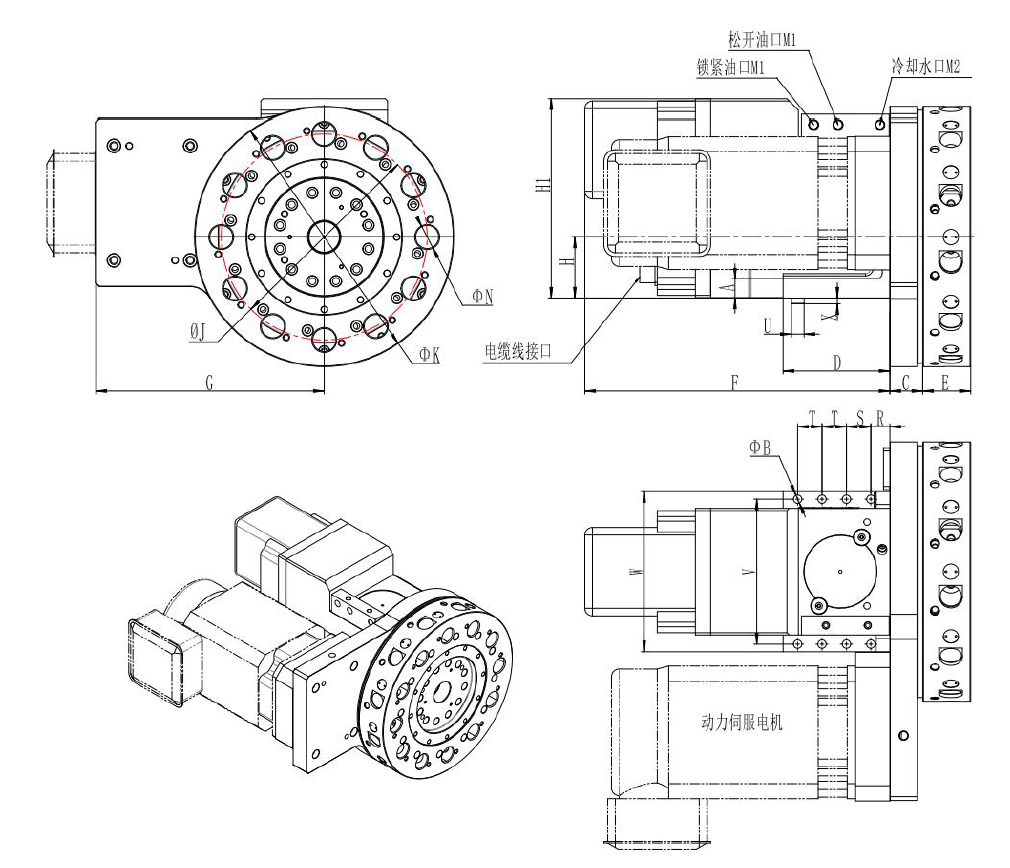

2.High-precision triple hirth coupling and hydraulic clamping devices for loosening and combining of power head are used to obtain high indexing accuracy and reliable clamping.

3.Separate spindle servo motor under simple control provides tool's driving force. Modular interface can adapt to a variety of the spindle motor, whose maximum power up to 11kw.

4.Each station can be assembled with a power tool, while only the work position provides the driving force. Tool block complies with international standards DIN69880 and DIN1809.

Key Features of Axial Servo Power Tooling Turrets

Servo Motor Drive:

Precision Control: Servo motors offer precise control over turret positioning, ensuring accurate and repeatable tool changes.

Speed and Efficiency: Servo-driven turrets can quickly and accurately index tools, reducing cycle times and increasing productivity.

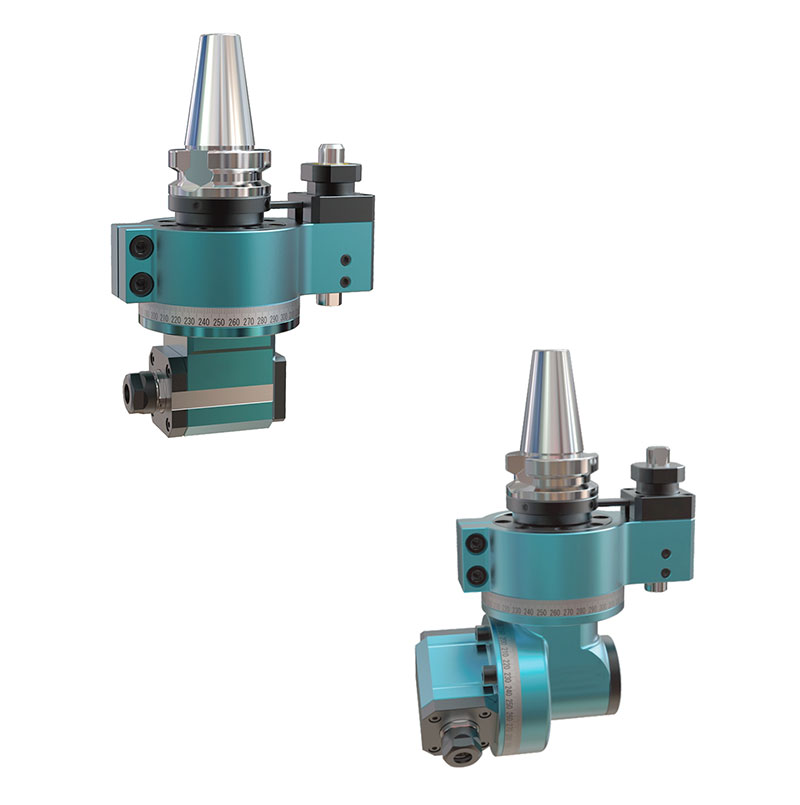

Axial Tooling Configuration:

Versatility: Axial tooling allows for tools to be mounted parallel to the spindle axis, providing greater flexibility for various machining operations such as turning, drilling, and milling.

Compact Design: The axial configuration typically results in a more compact turret design, saving space in the machining center and allowing for more efficient use of the workspace.

High Torque and Stiffness:

Robust Construction: Designed to handle high torque loads, ensuring stability and accuracy during heavy-duty machining operations.

Enhanced Rigidity: Increased stiffness minimizes tool deflection and vibration, improving the quality of the machined parts.

Automatic Tool Change:

Reduced Downtime: Automatic tool changing capabilities eliminate the need for manual intervention, leading to reduced downtime and increased machine utilization.

Multi-Tool Capacity: The turret can hold multiple tools, allowing for seamless transitions between different machining operations within a single setup.

Product Size

Product Parameters

| Model | Dimension | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | A | B | C | D | E | F | G | H1 | J | K | ||||||||||||||||||||||||||||||||||||||||||||

| D63A | 63 | 20 | 8- 11 | 41 | 135 | 49 | 380 | 223 | 225 | 240 | 300 | |||||||||||||||||||||||||||||||||||||||||||

| D80A | 80 | 25 | 8- 11 | 43 | 140 | 63 | 390 | 298 | 260 | 270 | 340 | |||||||||||||||||||||||||||||||||||||||||||

| D100A | 100 | 30 | 8- 13 | 53 | 170 | 70 | 400 | 313 | 300 | 340 | 410 | |||||||||||||||||||||||||||||||||||||||||||

| D125A | 125 | 35 | 8- 17 | 71 | 210 | 85 | 415 | 371 | 330 | 400 | 480 | |||||||||||||||||||||||||||||||||||||||||||

| M1 | M2 | N | R | S | T | U | V | W | X | |||||||||||||||||||||||||||||||||||||||||||||

| D63A | PT1/4 | PT1/4 | 20 | 24 | 30 | 30 | 15 | 165 | 185 | 7.5 | ||||||||||||||||||||||||||||||||||||||||||||

| D80A | PT1/4 | PT1/4 | 30 | 25 | 32 | 32 | 17 | 190 | 210 | 7.5 | ||||||||||||||||||||||||||||||||||||||||||||

| D100A | PT3/8 | PT3/8 | 40 | 34 | 40 | 30 | 20 | 220 | 250 | 9 | ||||||||||||||||||||||||||||||||||||||||||||

| D125A | PT3/8 | PT3/8 | 50 | 30 | 44 | 43 | 26 | 280 | 310 | 9 | ||||||||||||||||||||||||||||||||||||||||||||

| Item | Unit | Model | |||||||||||||||||||||||||||||||||||||||||||||||||

| D63A | D80A | D100A | D125A | ||||||||||||||||||||||||||||||||||||||||||||||||

| Center height | mm | 63 | 80 | 100 | 125 | ||||||||||||||||||||||||||||||||||||||||||||||

| Workstation | position | 8; 12 | 8; 12 | 8; 12 | 8; 12 | ||||||||||||||||||||||||||||||||||||||||||||||

| Power tool speed | rpm | 6000 | 5000 | 4000 | 3500 | ||||||||||||||||||||||||||||||||||||||||||||||

| Rotating time (including locking ) | sec. | 0.9 | 1. 1 | 1.4 | 1.8 | ||||||||||||||||||||||||||||||||||||||||||||||

| Total indexing time for 180*(including locking ) | sec. | 1.2 | 1.4 | 1.9 | 2.5 | ||||||||||||||||||||||||||||||||||||||||||||||

| Clamping force | kg | 1700 | 2600 | 3500 | 5200 | ||||||||||||||||||||||||||||||||||||||||||||||

| Hydraulic working pressure | MPa | 3.5±0.5 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Flow rate | L/min | 18 | 20 | 25 | 30 | ||||||||||||||||||||||||||||||||||||||||||||||

| Inertia of movement for tool-dis | kg ·m2 | 0.5 | 1.5 | 4 | 7 | ||||||||||||||||||||||||||||||||||||||||||||||

| Unbalancing torque | Nm | 10 | 15 | 40 | 60 | ||||||||||||||||||||||||||||||||||||||||||||||

| Indexing accuracy | ±4" | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Accuracy of repeatability | ±1.6" | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Tool holder size | mm | Φ20 | Φ30 | Φ40 | Φ50 | ||||||||||||||||||||||||||||||||||||||||||||||

| Tool holder type | DIN69880 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Toolshank coupling | DIN1809; DIN5480 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Max power ( S3-40%- 10min ) | kw | 2.2 | 3.7 | 5.5 | 7.5 | ||||||||||||||||||||||||||||||||||||||||||||||

| Motor( FANUC )( No available ) | α1/ 10000i | α2/ 10000i | α3/ 10000i | α6/ 10000i | |||||||||||||||||||||||||||||||||||||||||||||||

| Motor and tool transmission ratio | 1:1 | 1:1 | 1:1 | 1:1 | |||||||||||||||||||||||||||||||||||||||||||||||

| Weight( Not including motor ) | kg | 95 | 135 | 195 | 350 | ||||||||||||||||||||||||||||||||||||||||||||||