Product Details

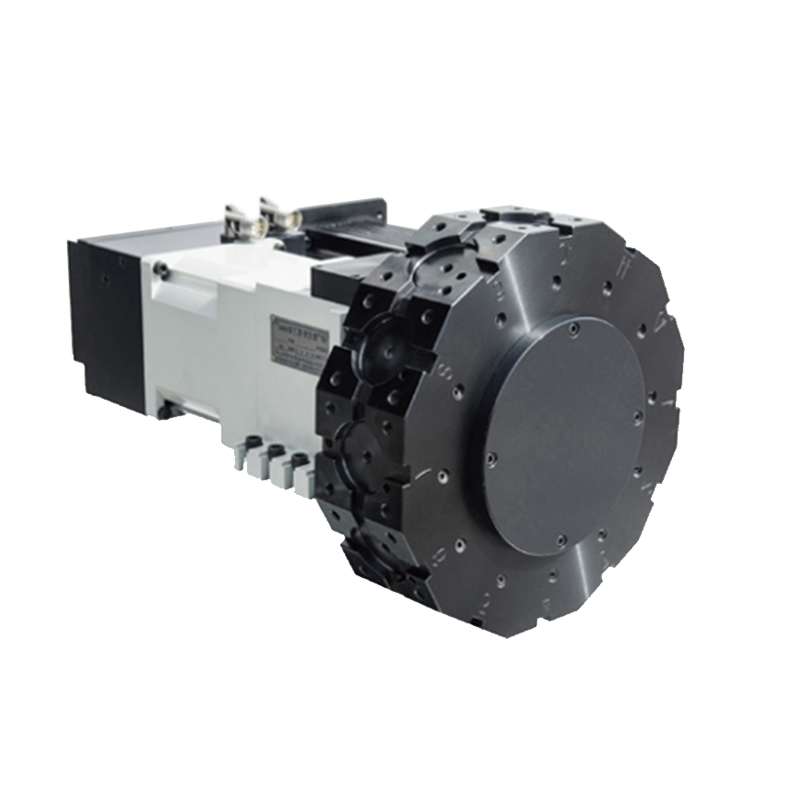

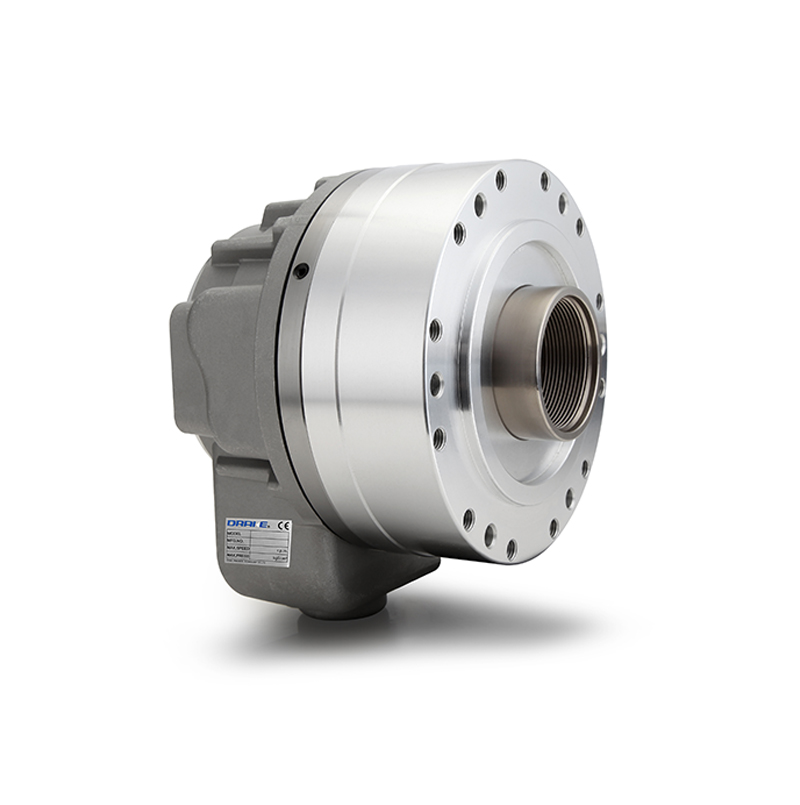

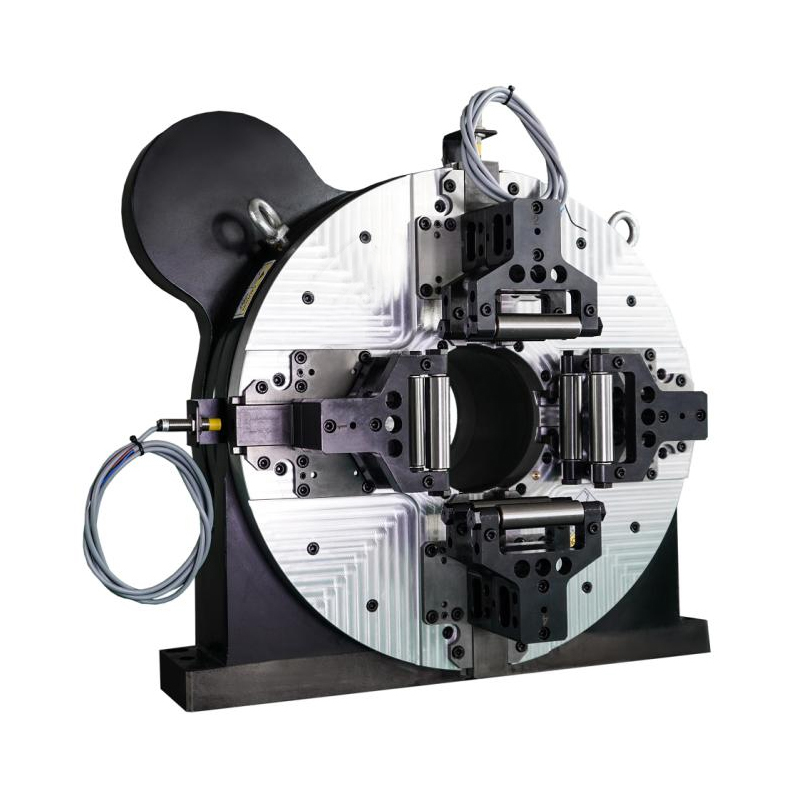

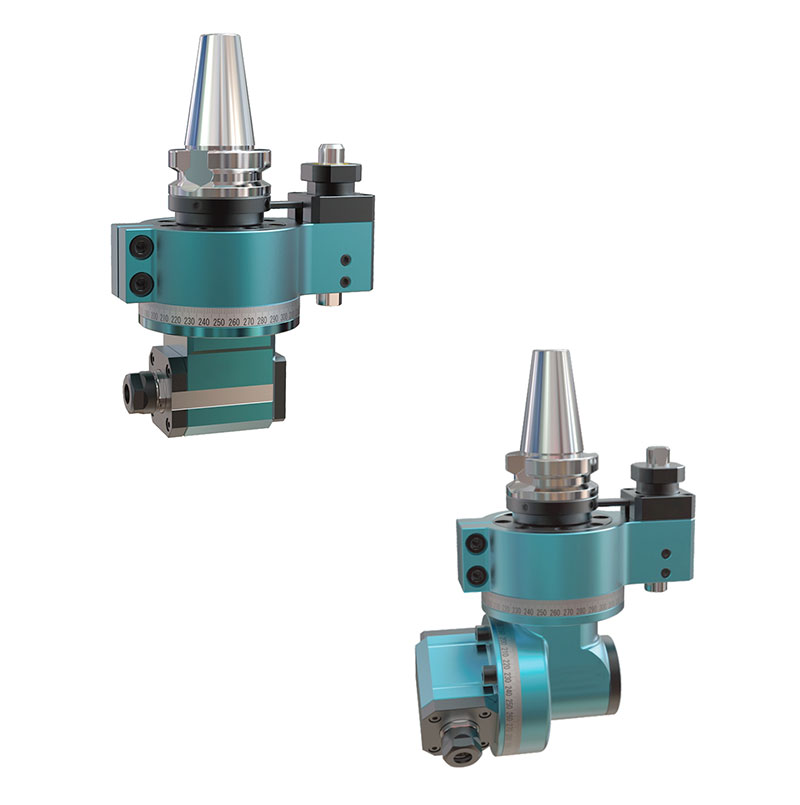

Product Feature:

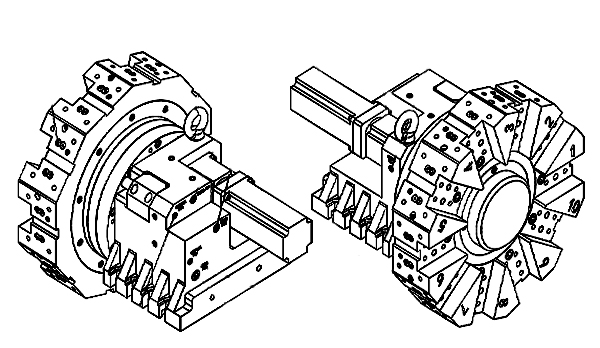

Lightweight, large through-hole rotary cylinders with through-holes for machining long-shaft parts.

Built-in check valve self-locking mechanism can prevent pipe damage, loss of pressure source, and ensure stable clamping of workpieces. Safe and reliable.

High-speed, high-life, internal components are imported.

Can be customized according to customer requirements.

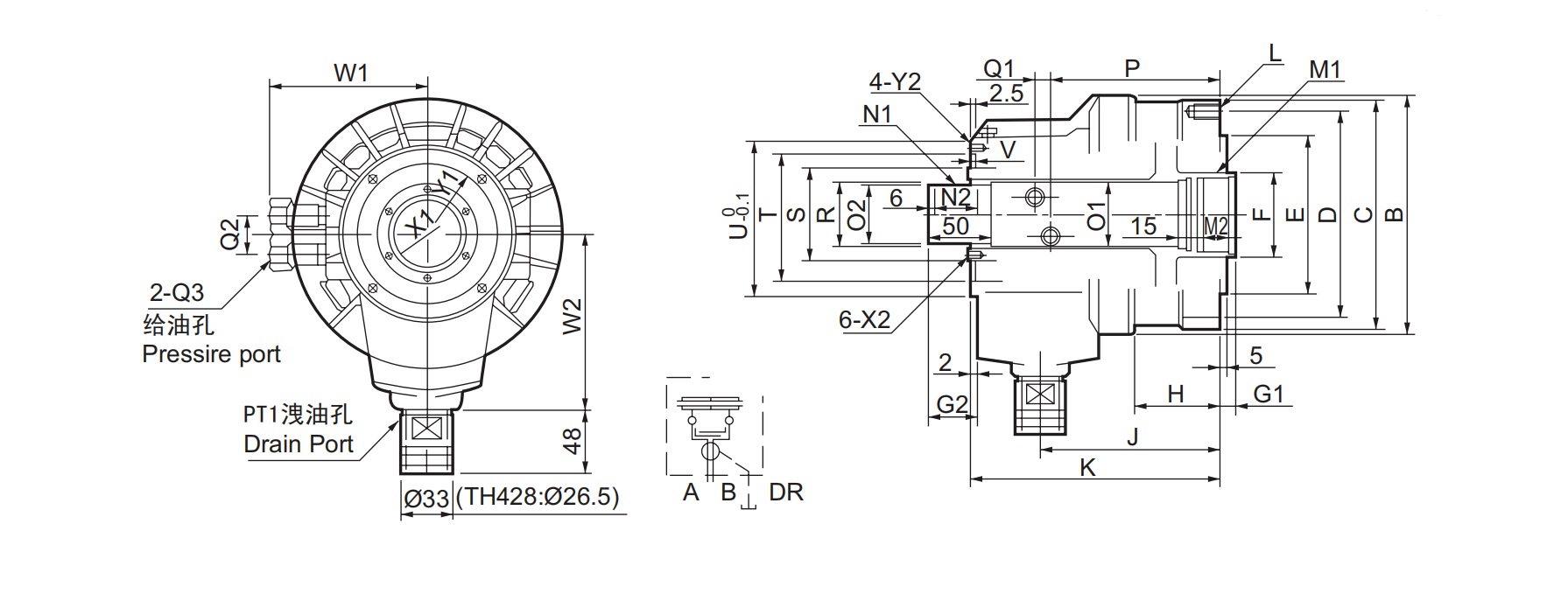

Product Size

Product Parameters

Please review the following parameter table. We offer various types of rotating hydraulic cylinders. If you need any assistance, feel free to leave your email and questions, and we will arrange for a professional to connect with you!

| Performance parameters | ||||||||

| Model/Spec. | Piston area (cm²) | Stroke (mm) | Hightest turnover number min-1(rpm) | Maximum working pressure MPa(kgf/cm²) | GD2 (kg.m²) | Total volume of oil drainage | Weight (kg) | |

| Press side | Pull side | |||||||

| TH428 | 53.2 | 50.5 | 10 | 8000 | 4.0(40) | 0.02 | 3 | 5.8 |

| TH536 | 69.8 | 67.5 | 15 | 8000 | 4.0(40) | 0.05 | 3 | 8.5 |

| TH646 | 97.3 | 87.9 | 15 | 7000 | 4.0(40) | 0.09 | 3 | 13.5 |

| TH852 | 146.8 | 136.6 | 20 | 6200 | 4.0(40) | 0.2 | 3.9 | 16.4 |

| TH1075 | 196.2 | 182 | 25 | 4700 | 4.0(40) | 0.4 | 4.2 | 25.8 |

| TH1291 | 250.6 | 234.1 | 30 | 3800 | 4.0(40) | 0.61 | 4.5 | 33 |

| TH1512 | 345.4 | 334.6 | 30 | 2800 | 4.0(40) | 1.5 | 7 | 50 |

| Size parameters | ||||||||||||||||||

| Model/Spec. | A I.D | B | C | D | E (h7) | F | G1 max. | G1 min. | G2 max. | G2 min. | H | J | K | L | M1 | M2 | N1 | N2 |

| TH428 | 90 | 130 | 120 | 100 | 80 | 40 | 10 | / | 35 | / | 45 | 127.5 | 155 | 6-M8×15 | M33×1.5 | 25 | M34×1.5 | 26 |

| TH536 | 105 | 150 | 135 | 115 | 100 | 50 | 15 | / | 40 | / | 47.5 | 125.5 | 170.5 | 6-M10×20 | M42×1.5 | 25 | M44×1.5 | 28 |

| TH646 | 125 | 169 | 156 | 130 | 100 | 65 | 15 | / | 40 | / | 60 | 135.5 | 193.5 | 12-M10×20 | M55×2 | 30 | M52×1.5 | 32 |

| TH852 | 150 | 198 | 188 | 170 | 130 | 70 | 20 | 0 | 45 | 25 | 66 | 145 | 198 | 12-M10×20 | M60×2 | 30 | M58×1.5 | 34 |

| TH1075 | 175 | 225 | 213 | 190 | 160 | 95 | 25 | / | 50 | / | 62 | 166.5 | 231 | 12-M10×22 | M85×2 | 35 | M84×2 | 40 |

| TH1291 | 205 | 255 | 240 | 215 | 180 | 110 | 30 | / | 55 | / | 64.5 | 180.5 | 250 | 12-M12×24 | M100×2 | 35 | M99×2 | 46 |

| TH1512 | 250 | 315 | 305 | 275 | 230 | 140 | 30 | / | 55 | / | 68 | 193 | 273 | 12-M16×32 | M130×2 | 45 | M134×2 | 46 |

| Model/Spec. | 01 H8 | 02 H8 | P | Q1 | Q2 | Q3 | R (g7) | S | T | U | V | W1 | W2 | X1 | X2 | Y1 | Y2 | N2 |

| TH428 | 30 | 28 | 101.5 | 11 | 24 | PT1/4 | 32 | 45 | 65 | 88 | 4 | 72 | 105 | / | / | 76 | M4×7 | 26 |

| TH536 | 38 | 36 | 119 | 11 | 24 | PT1/4 | 42 | 55 | 80 | 98 | 4 | 80 | 110 | / | / | 83 | M5×10 | 28 |

| TH646 | 50 | 46 | 127.5 | 12 | 30 | PT3/8 | 50 | 70 | 95 | 116 | 4 | 98 | 125 | 62 | M4×8 | 98 | M5×10 | 32 |

| TH852 | 55 | 52 | 135.5 | 12 | 32 | PT3/8 | 56 | 75 | 100 | 128 | 4 | 100 | 130 | 67 | M4×8 | 110 | M6×10 | 34 |

| TH1075 | 80 | 75 | 153.5 | 17 | 36 | PT3/8 | 81 | 100 | 125 | 158 | 5 | 115 | 160 | 92 | M4×8 | 145 | M6×10 | 40 |

| TH1291 | 95 | 91 | 165 | 21 | 34 | PT1/2 | 96 | 120 | 142 | 180 | 5 | 136 | 185 | 110 | M4×8 | 165 | M6×10 | 46 |

| TH1512 | 125 | 120 | 176.5 | 23 | 40 | PT1/2 | 130 | 160 | 195 | 227 | 6 | 160 | 210 | 171 | M6×10 | 215 | M6×10 | 46 |