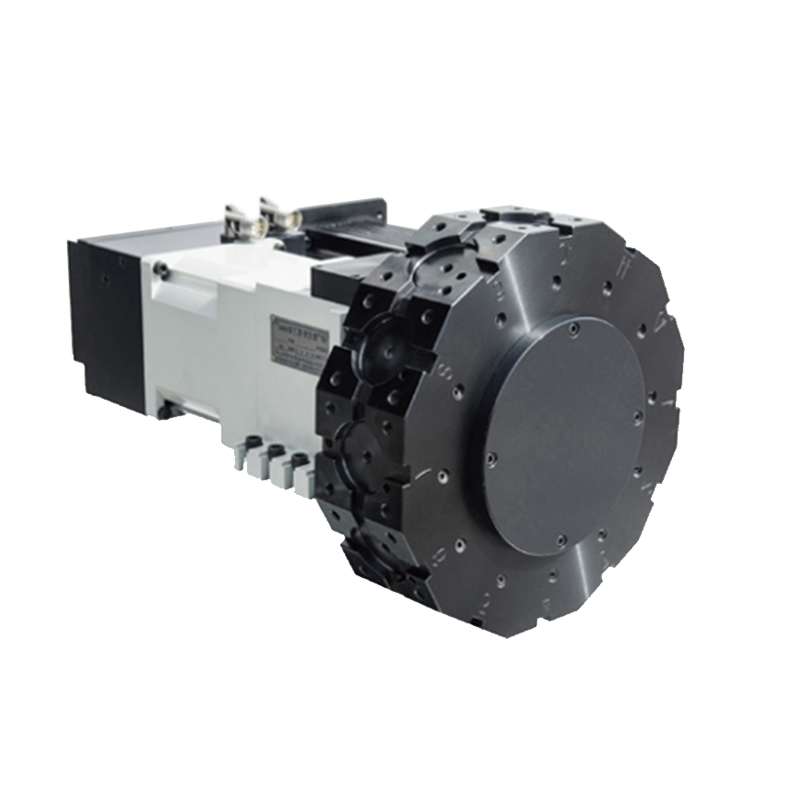

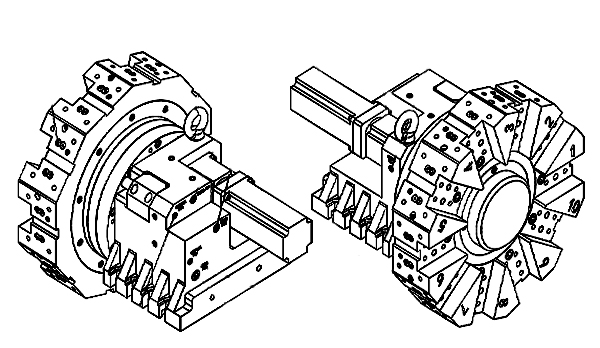

Product Details

Product Feature:

1.Adopt the advanced alloy steel material, all with the surface by surface hardening treatment, in order to improve the accuracy and durability.

2.With flange connection, A connection.

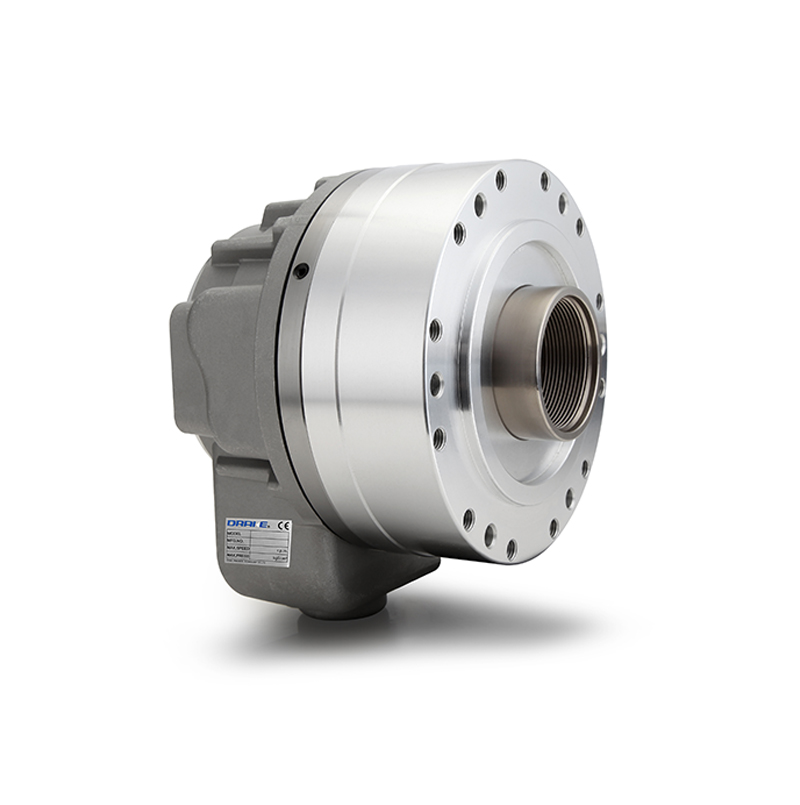

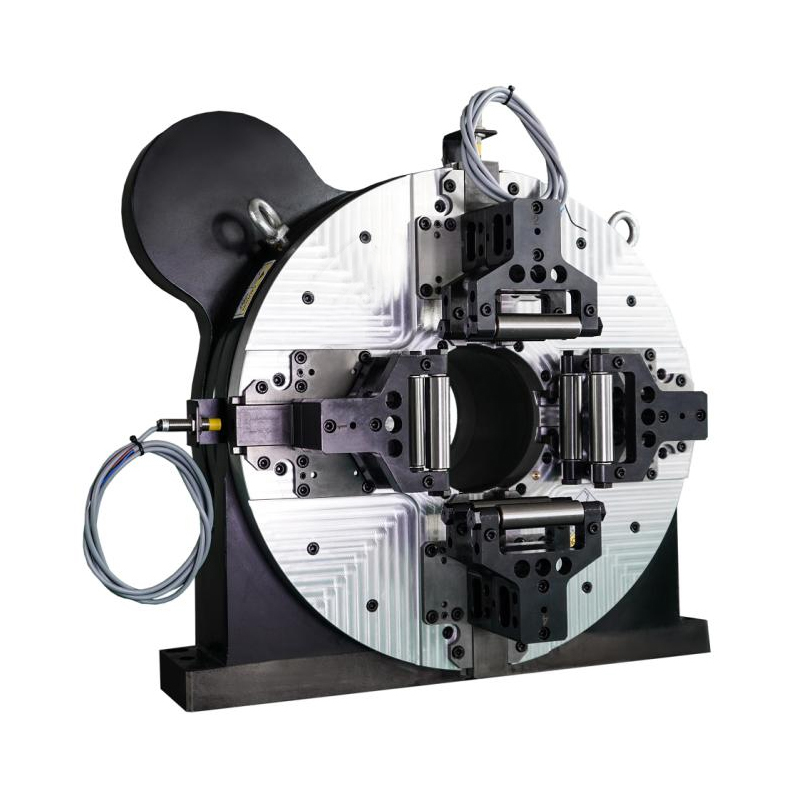

A pneumatic chuck is a highly efficient tool commonly used in machining for securing workpieces, and the pneumatic 3 jaw chuck is particularly popular for its versatility. The 3 jaw pneumatic chuck or pneumatic power chuck is designed to provide consistent clamping force through air pressure, making it ideal for automated processes. For applications requiring robust and reliable clamping, a 3 jaw air chuck is often used. These pneumatic power chucks are frequently found in pneumatic lathe chuck setups, where the pneumatic chuck 3 jaw configuration ensures precision and stability during high-speed operations.

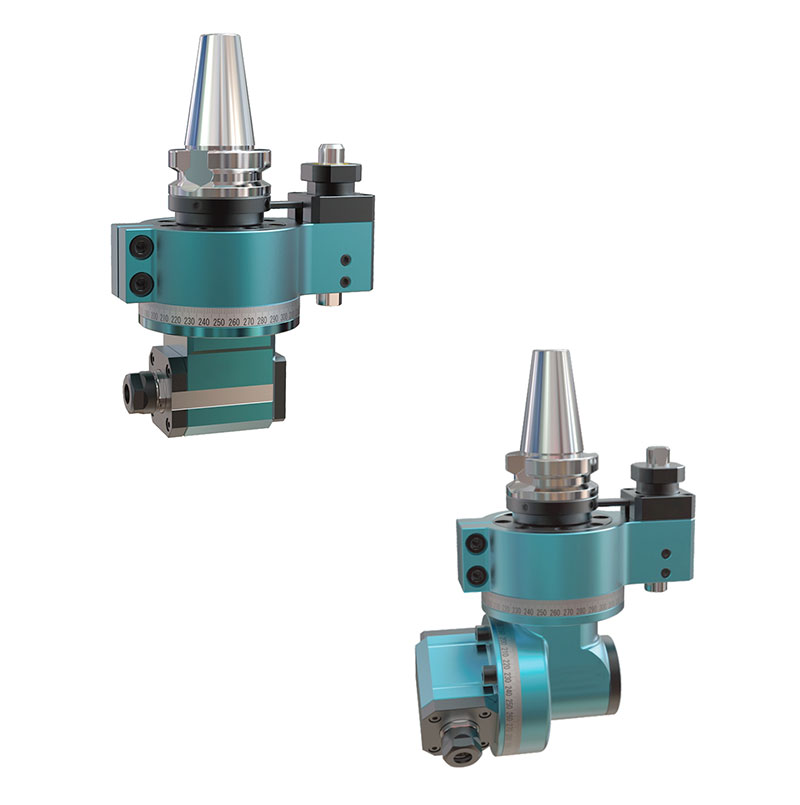

Drake is a leading enterprise with 15+ years of factory experience, specializing in machine tool accessories and offering OEM & ODM services. We cooperate with over 60 countries and provide one-stop purchasing solutions for for Power Chuck, Collet Chuck, Turret, Tool Holder, Rotary Cylinder, Laser Chuck, Tool magazine, and more. Our strict adherence to international quality standards and comprehensive product range ensures tailored processing solutions for diverse customer needs.

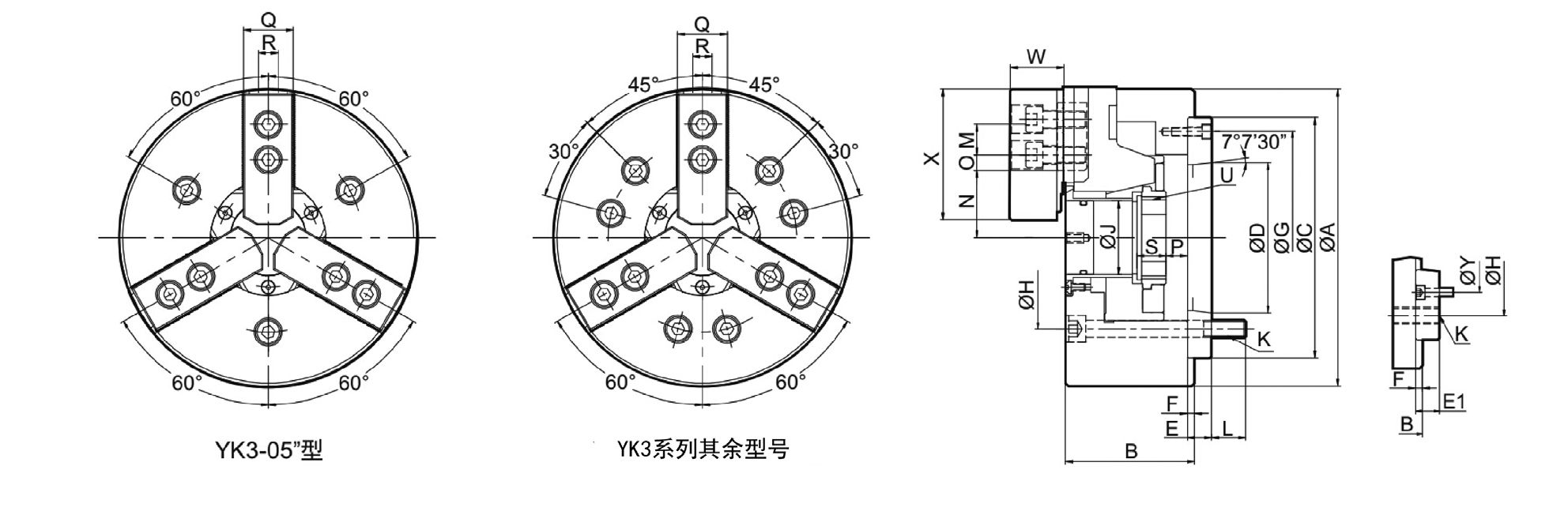

Product Size

Product Parameters

Discover the cnc power chuck model that suits your requirements from the following parameters. As a leading cnc power chuck manufacturer, if you have any questions regarding selection, pricing, or technical aspects, please don't hesitate to reach out. Feel free to leave your email along with your inquiries, and our dedicated team will promptly get in touch with you for professional assistance!

| Performance parameters | |||||||||||

| Model/Spec | Nose Of Spindle | Thru-Hole (Diametet) (mm) | Plunger Stroke(mm) | Jaw Stroke (Diameter) (mm) | Max.Speed (r.p.m) | Max.Pull Force(kgf) | Gripping Force(kgf) | Max.Hydr.Pressure (kgf/cm²) | Net weight (Kg) | Matching Cylinder | Gripping Range |

| YK3-05 | A4 | 33 | 10 | 5.4 | 7000 | 1730 | 3570 | 29 | 6.1 | TK536 | Φ10~Φ135 |

| YK3-06 | A5 | 45 | 12 | 5.5 | 6000 | 2140 | 5710 | 28 | 12.5 | TK646 | Φ15~Φ169 |

| YK3-08 | A6(A5) | 52 | 16 | 704 | 5000 | 2549 | 8769 | 27 | 23.6 | TK852 | Φ20~Φ210 |

| YK3-10 | A8(A6) | 75 | 19 | 8.8 | 4200 | 4280 | 11010 | 27 | 33.7 | TK1075 | Φ25~Φ254 |

| YK3-12 | A8 | 91 | 23 | 10.6 | 3300 | 5500 | 14380 | 27 | 55.3 | TK1291 | Φ30~Φ304 |

| YK3-15 | A11(A8) | 117.5 | 23 | 10.6 | 2500 | 7240 | 18250 | 25 | 106.8 | TK1512 | Φ49~Φ381 |

| YK3-18 | A11(A8) | 117.5 | 23 | 10.6 | 2000 | 7240 | 18250 | 25 | 171 | TK1512 | Φ79~Φ450 |

| YK3-21 | A15(A11) | 180 | 23 | 10.6 | 1800 | 9170 | 23860 | 24 | 234 | TK1512 | Φ105~Φ530 |

| YK3-24 | A15(A11) | 205 | 26 | 12 | 1400 | 10000 | 24500 | 21 | 284 | TK1512 | Φ135~Φ610 |

| YK3-32 | A15 | 205 | 34 | 18 | 800 | 10000 | 24500 | 21 | 560 | TK1512 | Φ205~Φ800 |

| Size parameter | |||||||||||||||||||||||||||

MODEL /SPEC. | A | B | C (h6) | D | E | E1 | F | G | H | J | K | L | M | N max. | N min. | O max. | O min. | P max. | P min. | Q | R | S | U | W | X | Y | Y |

| YK3-05 | 135 | 60 | 110 | 63.513 | 15 | - | 4 | 96 | 82.6 | 32.5 | 3-M8X1.25P | 15 | 14 | - | - | 19 | 6 | 1 | -9 | 25 | 10 | 20 | M40X1.5P | 31.5 | 62 | - | - |

| YK3-06 | 169 | 81 | 140 | 82.563 | 15 | - | 5 | 116 | 104.8 | 45 | 6-M10X1.5P | 16 | 20 | 32.35 | 59.6 | 24 | 7 | 11 | -1 | 31 | 12 | 19 | M55X2P | 37 | 73 | - | |

| YK3-08 | 210 | 91 | 170 | 106.375 | 17 | 25 | 5 | 150 | 133.4 | 52 | 6-M12X1.75P | 18 | 25 | 38.7 | 35 | 29.75 | 14.75 | 14.5 | -1.5 | 35 | 14 | 20.5 | M60X2P | 39 | 95 | 104.8 | 104.8 |

| YK3-10 | 254 | 100 | 220 | 139.719 | 18 | 28 | 5 | 190 | 171.4 | 75 | 6-M16X2P | 19 | 30 | 51.5 | 47.1 | 34 | 12 | 8.5 | -10.5 | 40 | 16 | 25 | M85X2P | 48 | 110 | 133.4 | 133.4 |

| YK3-12 | 304 | 110 | 220 | 139.719 | 18 | - | 6 | 190 | 171.4 | 91 | 6-M16X2P | 25 | 30 | 61.6 | 56.3 | 46 | 12 | 8 | -15 | 50 | 21 | 28 | M100X2P | 51 | 129 | - | |

| YK3-15 | 381 | 133 | 300 | 196.869 | 22 | 33 | 6 | 255 | 235 | 117.45 | 6-M20X2.5P | 27 | 43 | 82.3 | 77 | 46 | 13 | 7 | -16 | 62 | 22 | 43 | M130X2P | 66 | 165 | 171.4 | 171.4 |

| YK3-18 | 450 | 133 | 300 | 196.869 | 22 | 33 | 6 | 260 | 235 | 117.5 | 6-M20X2.5P | 28 | 43 | 82.7 | 76.7 | 79.25 | 13.75 | 7 | -16 | 62 | 24 | 42.5 | M130X2P | 66 | 165 | 171.4 | 171.4 |

| YK3-21 | 530 | 134 | 380 | 285.78 | 32 | 22 | 6 | 330 | 330 | 180 | 6-M24 | 35 | 60 | 112.5 | 107.2 | 60.5 | 24.5 | 13 | -15 | 65 | 25 | 38 | M190X3P | 73 | 180 | - | - |

| YK3-24 | 610 | 147 | 520 | 285.78 | 32 | 22 | 6 | 330 | 463 | 205 | 6-M24 | 35 | 60 | 131.9 | 125.9 | 87.5 | 24.5 | 16 | -10 | 65 | 25 | 38 | M215X3P | 73 | 180 | - | - |

| YK3-32 | 800 | 150 | 520 | 285.78 | 32 | 22 | 6 | 330 | 463 | 205 | 6-M24 | 35 | 60 | 162 | 153 | 153.5 | 24.5 | 16 | -10 | 65 | 25 | 38 | M250X3P | 73 | 180 | - | - |