Product Details

Product Feature:

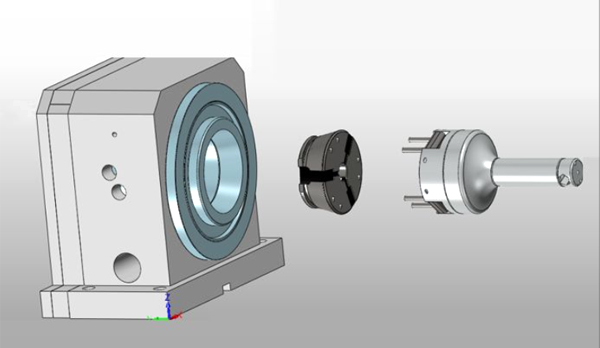

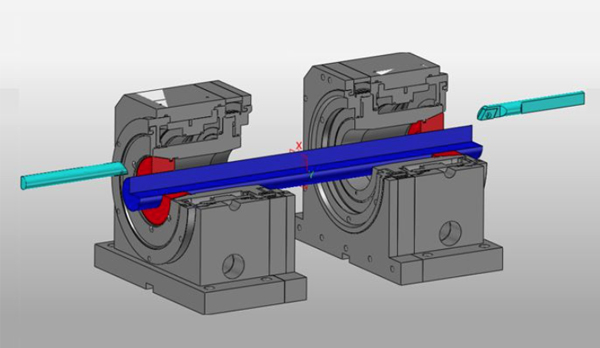

This series of chuck comes with built-in cylinder structure, adopt the advanced alloy steel material, all with the surface by surface hardening treatment, in order to improve the accuracy and durability Without flange connection, D connection.

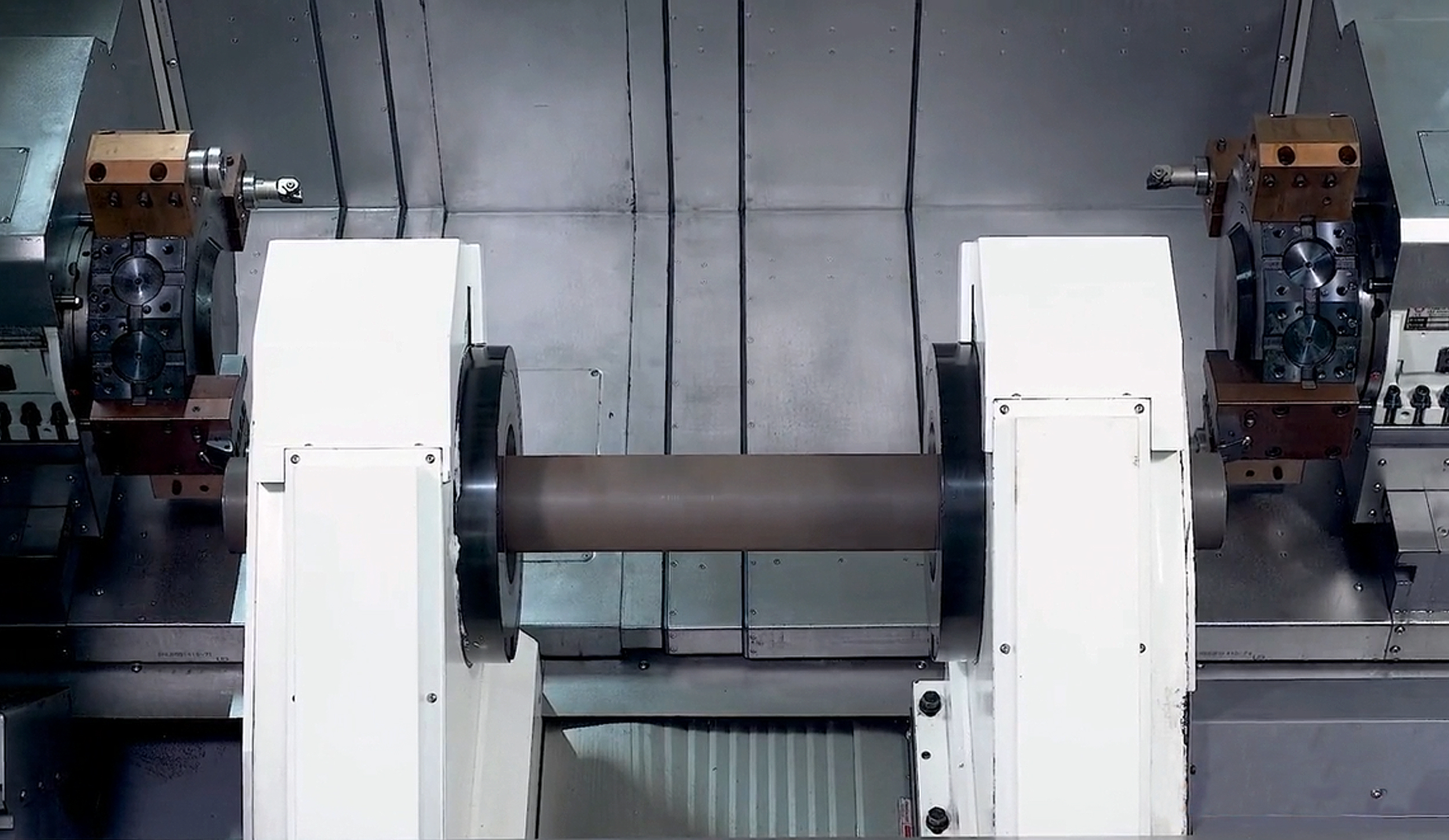

Drake is a leading enterprise with 15+ years of factory experience, specializing in machine tool accessories and offering OEM & ODM services. We cooperate with over 60 countries and provide one-stop purchasing solutions for for Power Chuck, Collet Chuck, Turret, Tool Holder, Rotary Cylinder, Laser Chuck, Tool magazine, and more. Our strict adherence to international quality standards and comprehensive product range ensures tailored processing solutions for diverse customer needs.

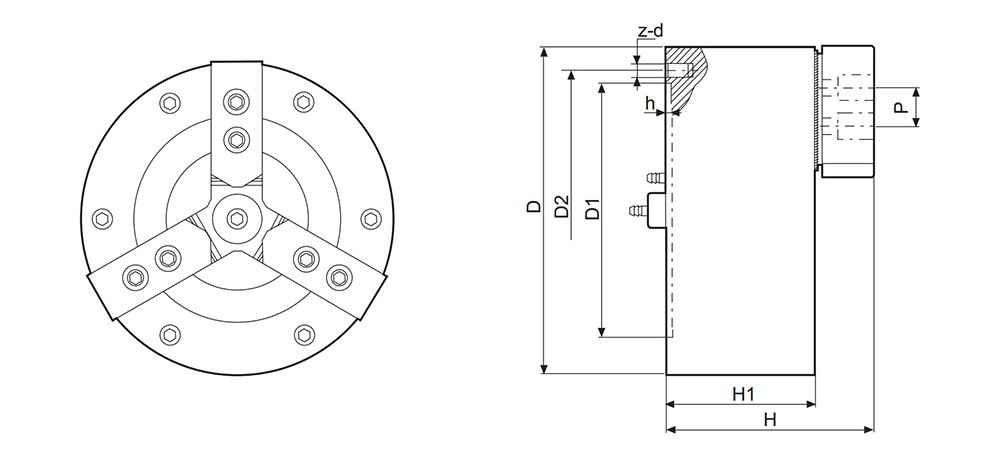

Product Size

Product Parameters

Discover the cnc power chuck model that suits your requirements from the following parameters. As a leading cnc power chuck manufacturer, if you have any questions regarding selection, pricing, or technical aspects, please don't hesitate to reach out. Feel free to leave your email along with your inquiries, and our dedicated team will promptly get in touch with you for professional assistance!

Our product lineup features a variety of advanced chuck solutions, including the three jaw chuck, pneumatic chuck 3 jaw, and pneumatic 3 jaw chuck, designed for precision and efficiency. For specialized needs, we offer the 3 jaw air chuck and 3 jaw pneumatic chuck, ensuring reliable performance in demanding applications. Our pneumatic lathe chuck and pneumatic power chucks provide excellent versatility for machining tasks, while the pneumatic power chuck delivers robust and consistent clamping force for enhanced productivity.

| Performance parameters | ||||||||

| Model/Spec. | Jaw stroke (diameter)(mm) | Maximum static clamping force (Kgf) | Maximum static holding force (Kgf) | Permissible pressure (Mpa) | Limit speed (r/min) | Clamping range | Holding range | Net weight (kg) |

| QS3-04" | 3.2 | 2040 | 1170 | 0.4-0.8 | 4500 | 2-120 | 15-120 | 5.2 |

| QS3-05" | 3.7 | 2850 | 1830 | 0.4-0.8 | 4000 | 3-140 | 15-140 | 8 |

| QS3-06" | 4.2 | 4890 | 2650 | 0.4-0.8 | 3600 | 4-180 | 18-180 | 14 |

| QS3-08" | 5 | 7140 | 4280 | 0.4-0.8 | 3300 | 5-220 | 20-240 | 23 |

| QS3-10" | 6.5 | 9280 | 6120 | 0.4-0.8 | 3000 | 10-260 | 30-280 | 35 |

| QS3-12" | 8.5 | 14070 | 9480 | 0.4-0.8 | 2500 | 20-350 | 40-360 | 70 |

| QS3-15" | 12 | 19780 | 15000 | 0.4-0.8 | 2000 | 30-420 | 60-440 | 118 |

Size parameters

| Model/Spec. | D | D1 | D2 | H | H1 | h | p | z-d |

| QS2-04" | 115 | 72 | 100 | 96 | 72 | 3 | 16 | 3-M8 |

| QS2-05" | 145 | 95 | 108 | 118 | 85 | 4 | 18 | 3-M8 |

| QS2-06" | 180 | 130 | 142 | 130 | 93 | 4 | 20 | 3-M8 |

| QS2-08" | 208 | 165 | 180 | 136 | 100 | 5 | 25 | 3-M10 |

| QS2-10" | 252 | 206 | 226 | 143 | 102 | 5 | 30 | 3-M12 |

| QS2-12" | 322 | 270 | 290 | 160 | 115 | 6 | 30 | 6-M12 |

| QS2-15" | 400 | 340 | 368 | 168 | 118 | 6 | 43 | 6-M16 |