Power Chuck

Introduce foreign advanced technology and management concept, High precision processing equipment, and High-end measuring instruments; Have a high-quality professional team, Strictly follow the ISO9001-2008 quality control system, Perfect sales network, and good after-sales service, The management platform of informatization interaction, scientific management, standardized specifications, standardized operation, and specialized manufacture, Make a famous brand of "DRAKE".

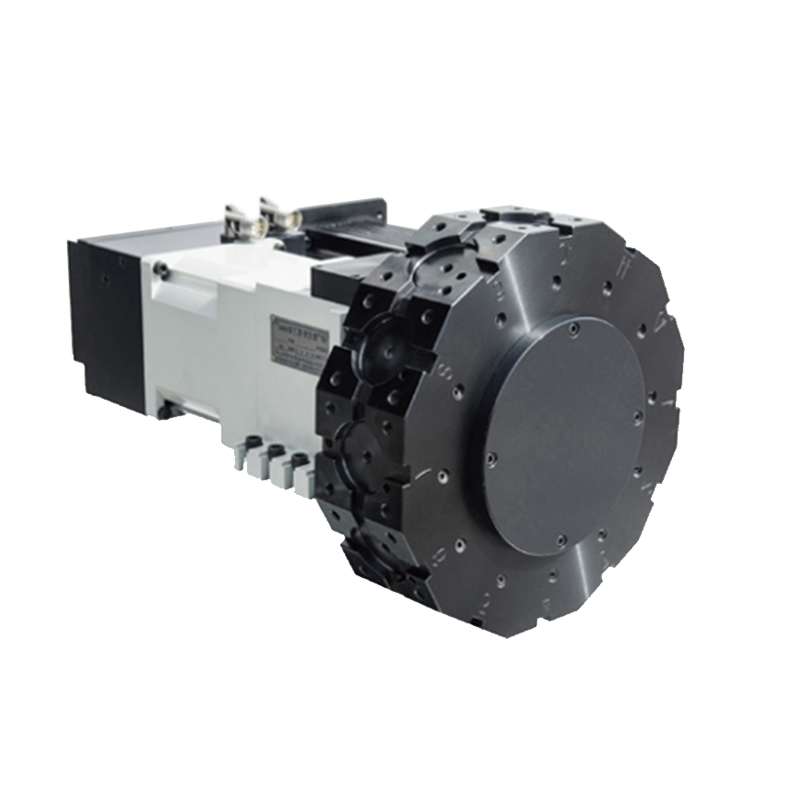

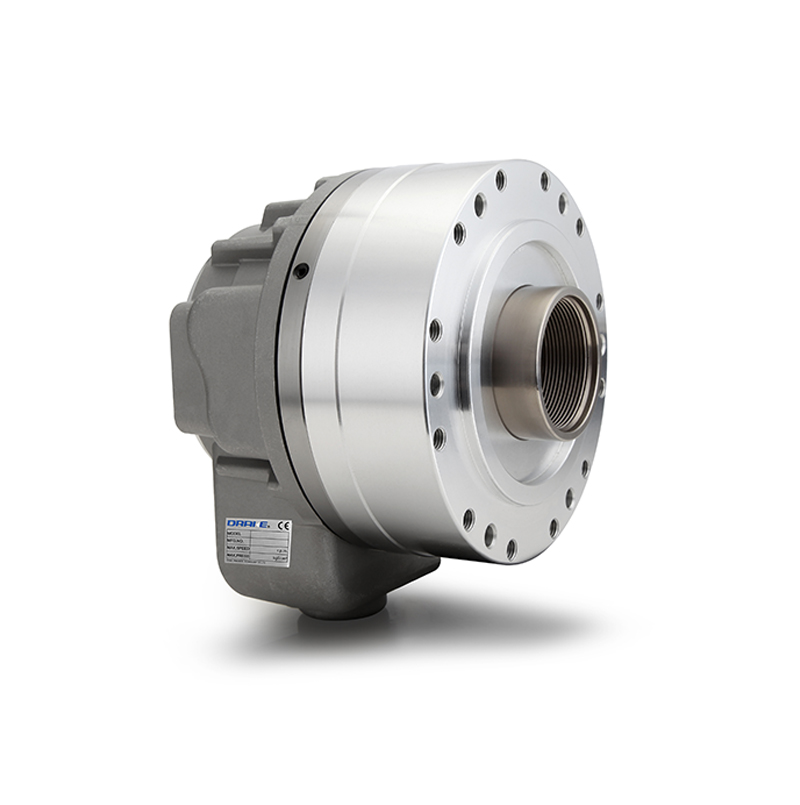

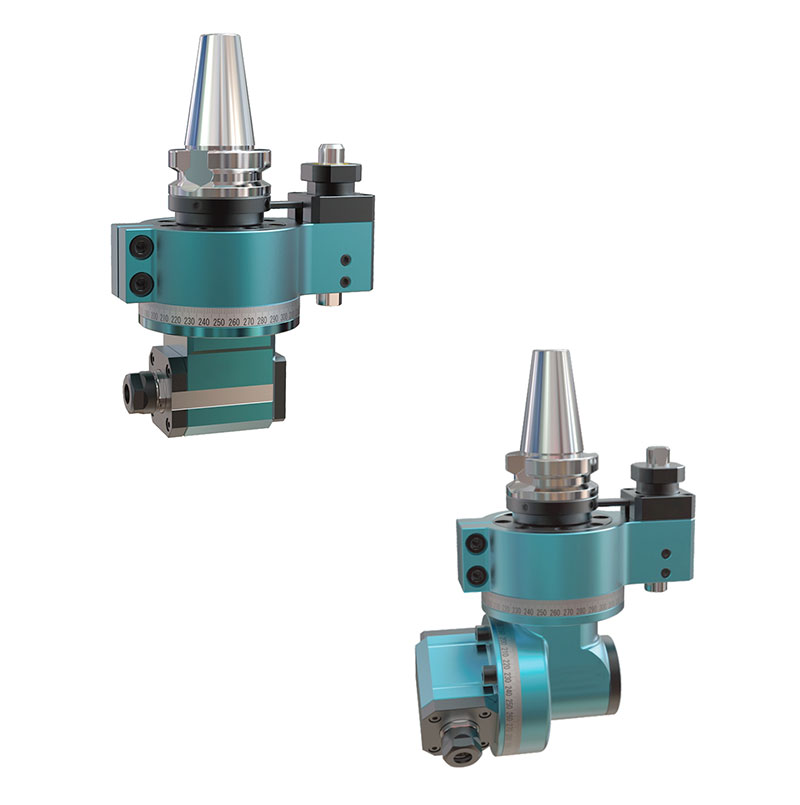

Our products include power chucks, collet chucks,Turret,Tool Holder,rotary cylinders, Tool magazine and so on. It can also be made according to the user’s special needs, and provides you with the best-integrated solutions for the clamping mechanism. Depending on “reasonable price, reliable quality, considerate service, constant innovation’’, all of those products have been well recognized by users both old and new, and they are widely applied to NC lathes, common lathes, machining centers, drillers and millers, welding machines, pipe threading machine, production line equipment, and automatic control system, etc.

Please submit your request and email and we'll get back to you within 24 hours!

Drake precision technology (changzhou) Co.,Ltd. is a technology enterprise. In order to meet demands of the market, Drake is specialized in the research, development, production and sale of fixture. DRAKE offers a wide range of standard power chuck types and styles for a variety of manufacturing operations. You can expect unbeatable value as quality, service and price will vary.

A power chuck is a type of lathe chuck that uses hydraulic or pneumatic cylinders to open and close its jaws. This allows for precise positioning and securing of workpieces, making the power chuck an essential tool for various machining applications.

Power Chuck Vs Manual Chuck For Workholding

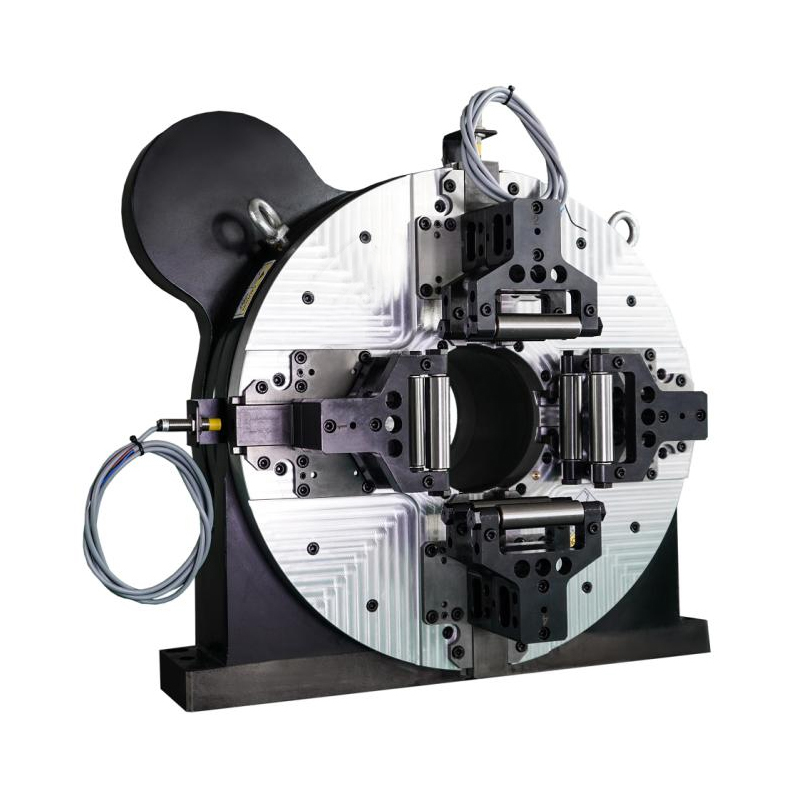

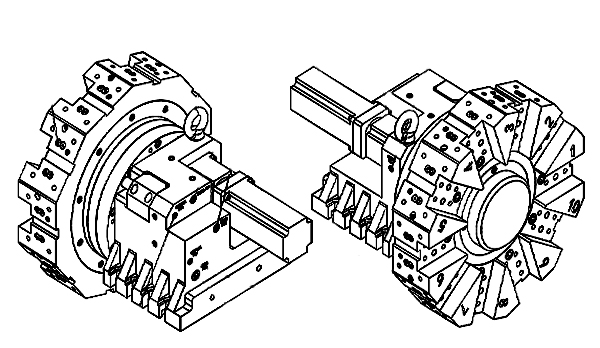

DRAKE Power Chuck diameters range from 3" to 79" and we can handle all your special workpiece clamping requirements. Power chucks are available in 1, 2, 3 and 4 jaw configurations as standard, and 6-jaw power chucks and various top jaw configurations are available as custom solutions (build to order).

1,2,3,4 & 6 Jaws

Standard or large through holes

Closed center

Long chin stroke

Horizontal and vertical applications

DRAKE Standard Power Chucks

Standard power chucks are a type of workholding device that are widely used in various manufacturing industries. Standard power chucks can be divided into several types depending on their design and application.

Our product range includes high-quality pneumatic chuck, CNC power chuck, and power chuck solutions designed to meet the needs of modern machining. Whether you are looking for a hydraulic chuck for lathe, a CNC lathe chuck, or reliable power chucks, we have you covered. Our advanced CNC chucks are perfect for precision operations on a chuck CNC machine. For specific applications, we also offer pneumatic chuck 3 jaw and CNC hydraulic chuck options. As one of the leading power chuck manufacturers, we are committed to providing innovative and durable products tailored to your requirements.

Two-jaw power chucks: These chucks have two jaws that move in unison to clamp the workpiece. They are often used for holding square or rectangular workpieces, and are suitable for applications that require a simple and quick changeover.

Three-jaw power chucks: These chucks have three jaws that move in unison to clamp the workpiece. They are the most common type of power chucks and are used for round or hexagonal workpieces. Three-jaw chucks provide high accuracy and stability, making them suitable for precision machining applications.

Four-jaw power chucks: These chucks have four jaws that can be independently adjusted to clamp irregularly shaped workpieces. They provide a greater range of clamping options than three-jaw chucks and are often used for holding square or rectangular workpieces.

Six-jaw power chucks: Six-jaw power chucks have six jaws that can be adjusted individually to clamp irregularly shaped workpieces. They provide a higher clamping force than four-jaw chucks and are used for heavy-duty applications.

Self-centering power chucks: These chucks have jaws that automatically center the workpiece, ensuring high accuracy and stability. They are often used in CNC turning centers and other high-precision machining applications.

How To Fix A Stuck CNC Machine Chuck

DRAKE Power Chucks offer a high precision general purpose chuck for virtually any turning application. The lightweight design allows for faster speeds and, combined with the optional quick-change jaw system, is an excellent choice for reducing machine cycle times while saving energy and spindle wear.

They offer higher clamping forces and greater accuracy, making them particularly suitable for heavy-duty machining of disk and bar components and high-precision finishing of deformation-prone workpieces. The available jaw options are compatible with industry standards in the U.S., Europe and Asia, making top-of-the-line tools easy and economical to purchase.

How can I help you?

Drake International Trade Co., Ltd (Export Platform)

Add.: Yaoguan, WuJin District, Changzhou, Jiangsu, China 213000

Contact Person: Joanna Zhou

Mobile/Whatsapp/Wechat: +8613815018181

Tel: +86 519 8385 6060

Skype: zhou.joanna9

Email: joanna@drakecn.com

Read More