Nov. 06, 2019

The working principle of the hydraulic transmission is to use this oil as the working medium, relying on the change of the sealing volume to transmit the movement, and relying on the external pressure of the oil to transmit the power. In fact, the hydraulic transmission is an energy conversion device that converts mechanical energy into hydraulic energy that is easy to transport, and then converts hydraulic energy into mechanical energy to drive the working mechanism to perform various required actions.

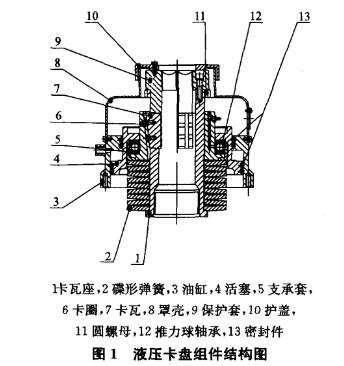

The hydraulic chuck is mainly composed of cylinders, pistons, collars, support sleeves, slips, disc springs, slips, protective sleeves, protective covers, thrust ball bearings, seals and other parts and components, as shown below.

The working principle of the hydraulic chuck is that the hydraulic oil enters the oil cylinder from the oil inlet of the oil cylinder during operation. The oil cylinder and the piston form a closed cavity. As the pressure increases, the piston moves down under the action of the pressure oil, and the card is pushed by the thrust ball bearing. The ring and the support sleeve are moved down together, so that the disc spring is compressed, and the buckle moves along the three cylinders to move horizontally away from the center of the circle, thereby achieving the purpose of loosening the drill rod.

When the drill pipe needs to be clamped, the operation is changed to the valve to open the hydraulic control valve to the valve. The oil in the closed chamber of the chuck passes through the oil pipe, and the hydraulic control check valve communicates with the reversing valve and the mailbox. At this time, the closed cavity has no pressure, and the disc is closed. The spring is also manually reset by the elastic force, and pushes the support sleeve, the collar, the thrust ball bearing and the piston upward, and drives the three slips to make a centripetal horizontal movement, thereby achieving the purpose of clamping the drill rod.