Feb. 28, 2025

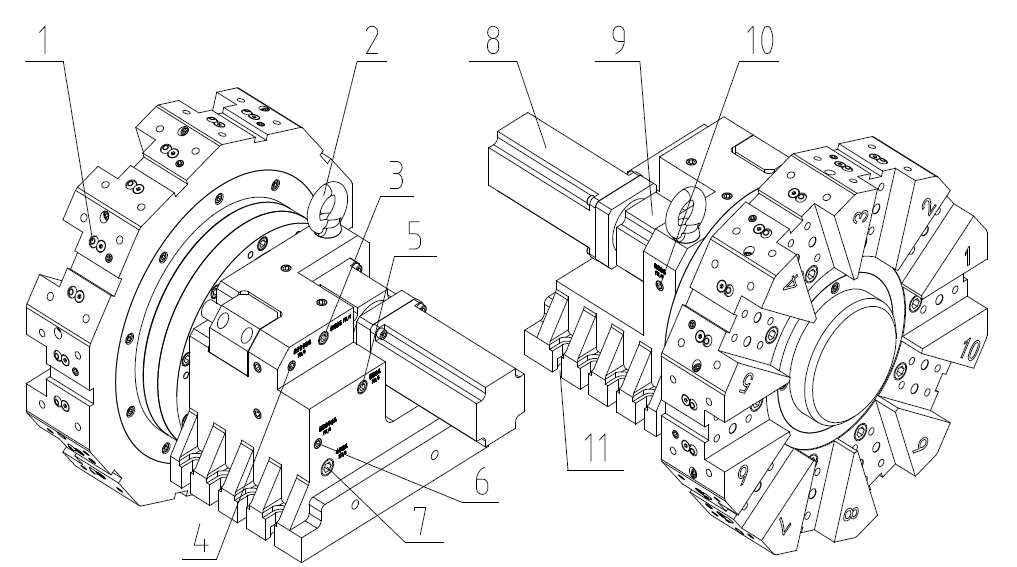

Introduction to external functions

1、Coolant outlet

2、Rings

3、Loosen the oil hole

4、Loosen the signal oil hole

5、Lock the oil hole

6、Tighten the signal oil hole

7、Coolant inlet

8、Servo motor

9、Reducer

10、Lubricating oil hole

11、Dowel hole

Servo motor (8) is the power source of the tool rest;

The box body is fixed on the machine tool and is based on the positioning pin (11);

The coolant inlet (7) will guide the coolant, flow through the box to the cutter head, and then flow out from the coolant outlet on the cutter head;

At the gear transmission place of the turret, lubricating oil is added through the lubricating oil hole (10), which can reduce noise and achieve good gear transmission.