Product Details

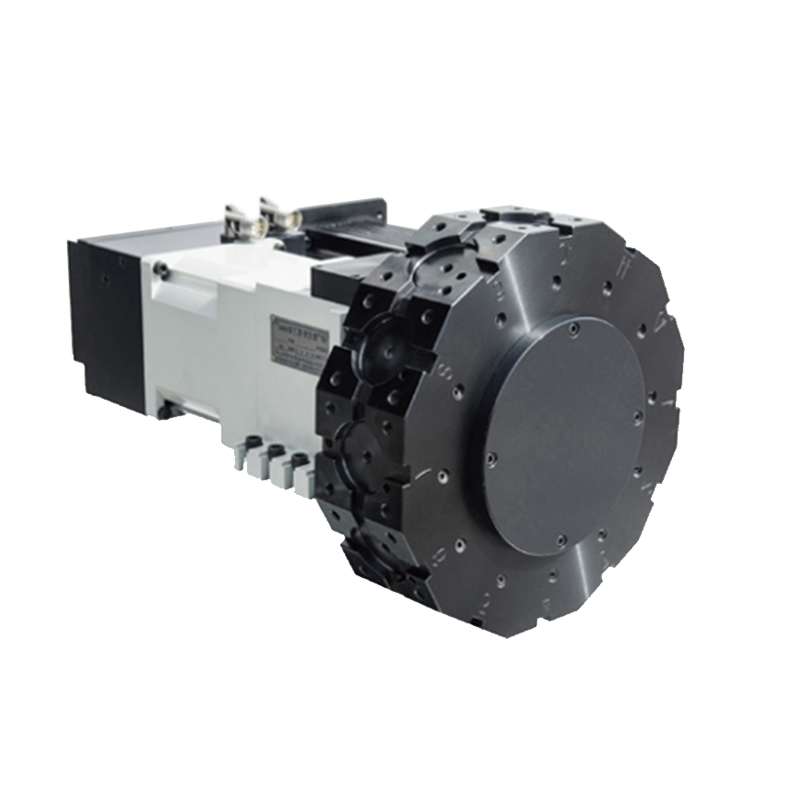

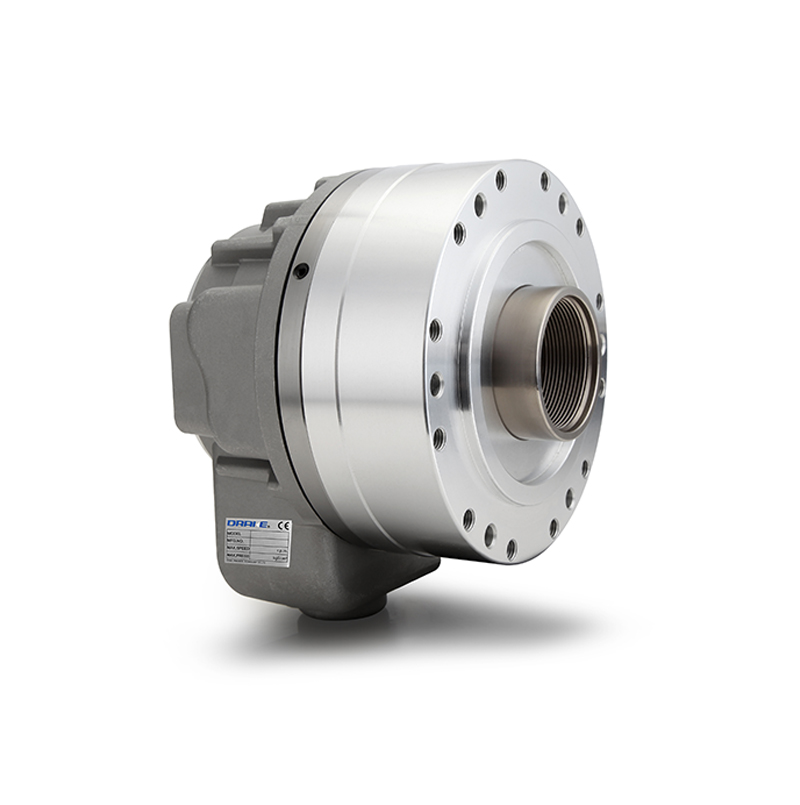

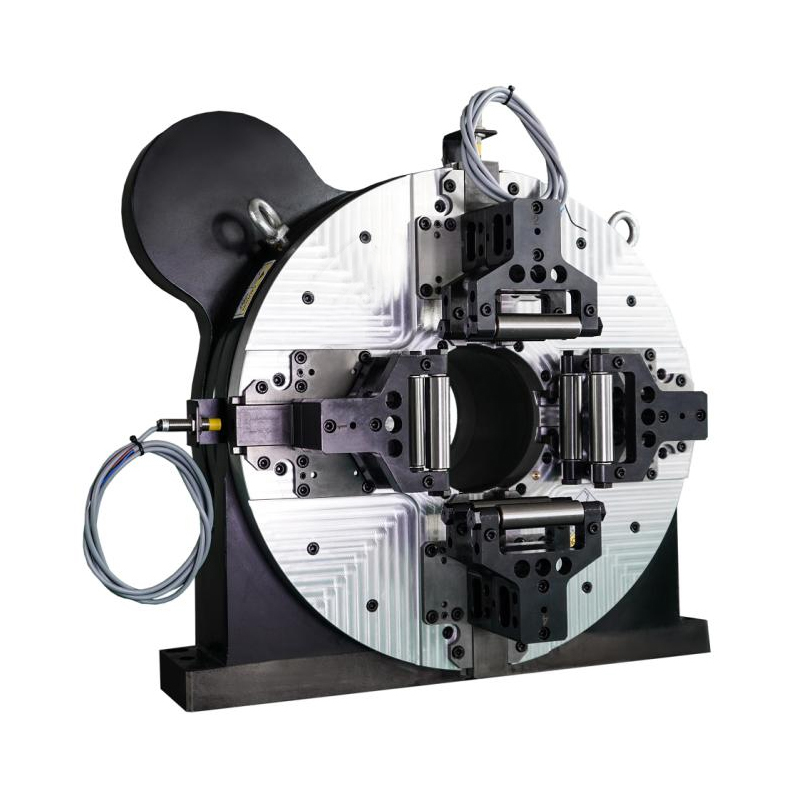

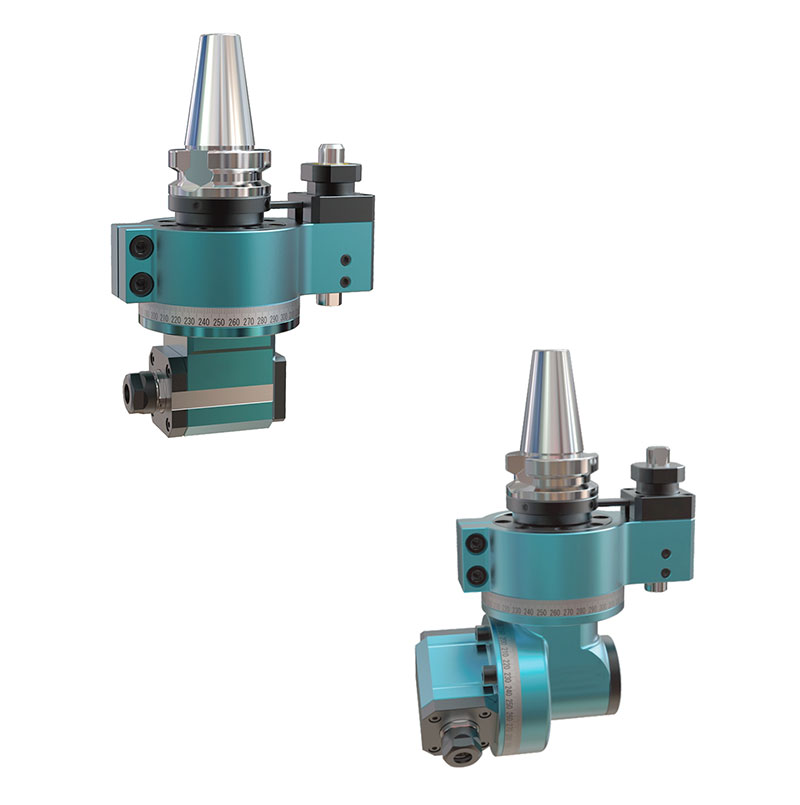

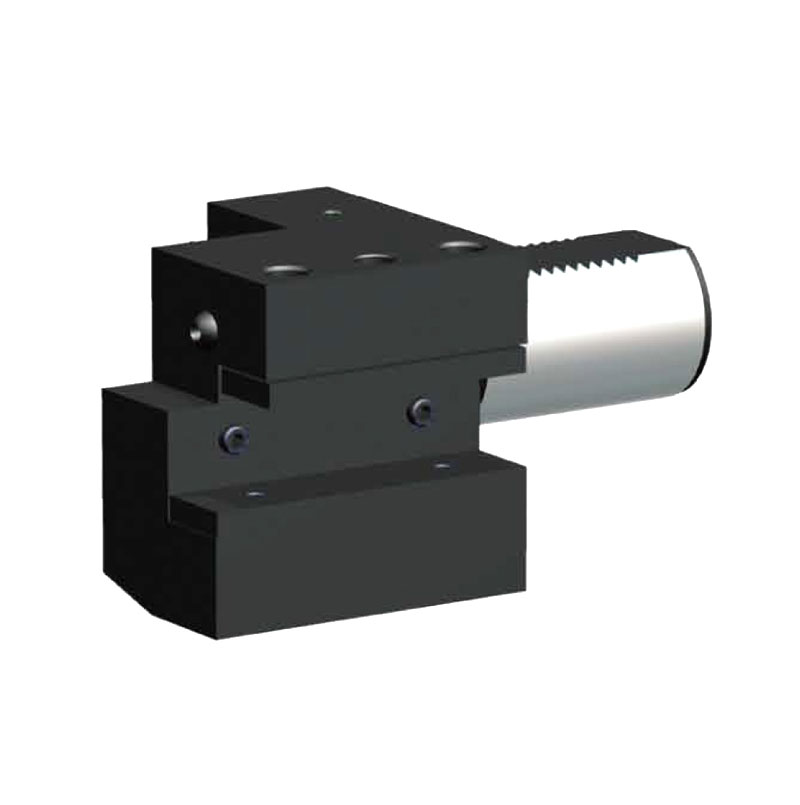

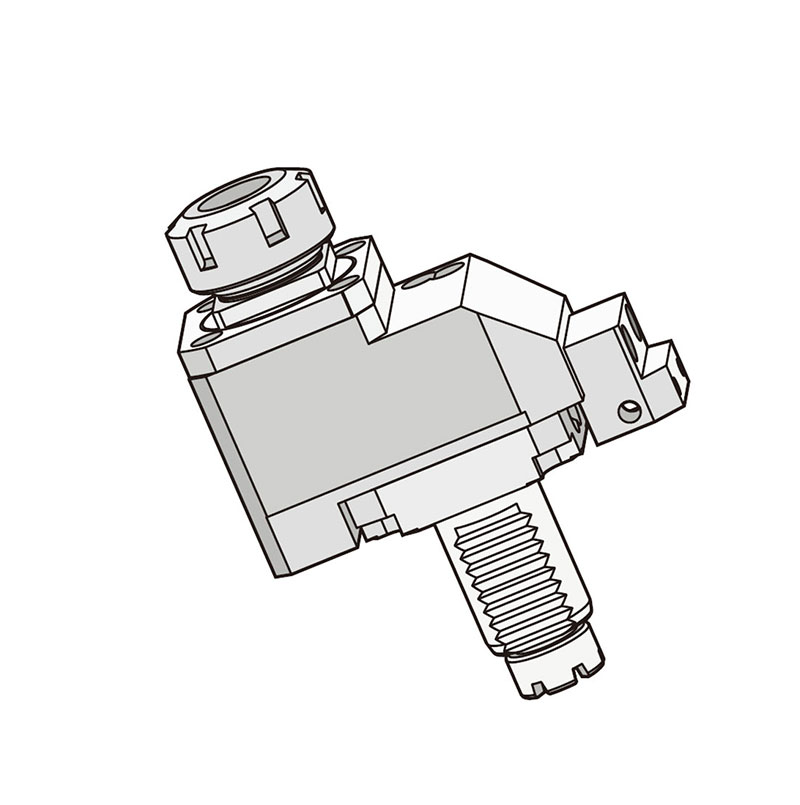

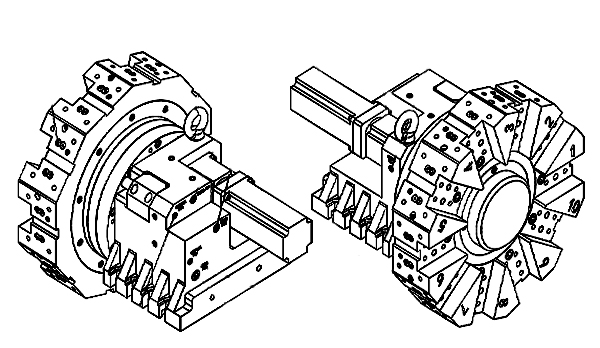

If you're seeking a superior tool holding solution that can revolutionize your machining operations, look no further than the JHS Hydraulic Fixing Chuck. With its enhanced clamping force, improved tool life, quick tool changes, and versatile application, this chuck is a game-changer in the world of machining. Experience unparalleled performance, reliability, and precision with the JHS Hydraulic Fixing Chuck and unlock a new level of efficiency and productivity in your workshop.

Product Features:

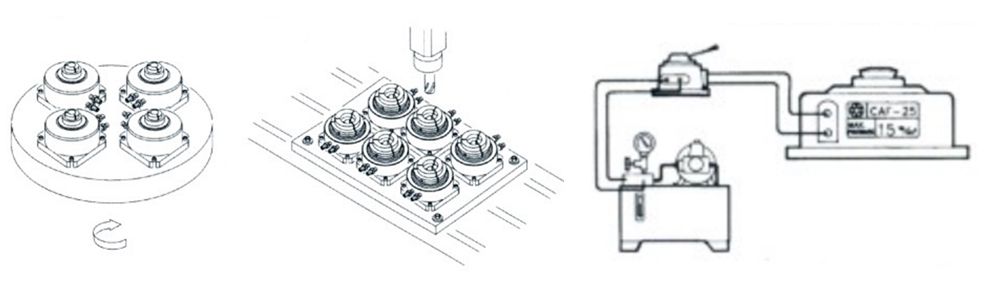

Suitable for drilling machines, tapping machines, iron beds, central processing machines, disc multi-station processing machines.

It is more convenient to use the interchangeable auxiliary claws and save the cost of the collet caused by product changes.

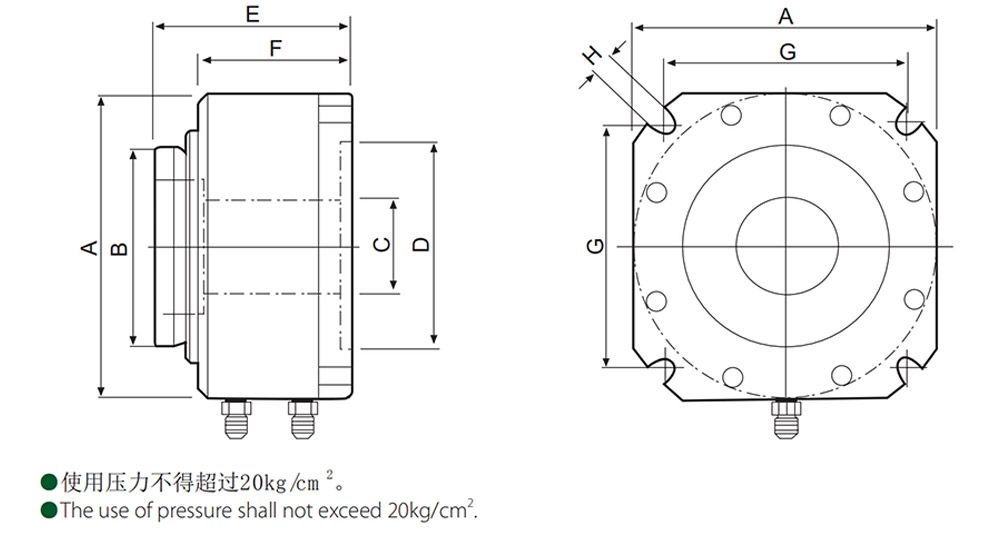

Product Size

Product Parameters

Discover the CNC collet chuck model that suits your requirements from the following parameters. As a leading collet chuck manufacturer, if you have any questions regarding selection, pricing, or technical aspects, please don't hesitate to reach out. Feel free to leave your email along with your inquiries, and our dedicated team will promptly get in touch with you for professional assistance!

Performance Parameters | |||||||

| Model/Spec. | Power source | Working pressure (kg/cm²) | Max.chuck diameter (mm) | Through-hole aperture (mm) | Clamping torque (N.m) | Matching jaw | Net weight (kg) |

| JHS-40" | Oil pressure | 20 | ∮50 | ∮38 | 35 | C-40 | 8.5 |

| JHS-70" | Oil pressure | 20 | ∮90 | ∮68 | 40 | C-70 | 13.1 |

| JHS-90" | Oil pressure | 18 | ∮90 | ∮87 | 40 | C-70 | 15.5 |

| Size parameters | ||||||||

| Model/Spec. | A | B | C | D | E | F | G | H |

| JHS-40" | 144 | 95 | 38 | 100 | 96 | 73 | 115.3 | 11 |

| JHS-70" | 188 | 135 | 68 | 155 | 94 | 73 | 146.4 | 11 |

| JHS-90" | 206 | 135 | 87 | 170 | 95 | 73 | 169.7 | 13 |

Note: The clamping torque is measured by clamping a 20 mm round bar at 20 kg/cm2.

★The above product data is for reference only, can be changed according to the needs of the workpiece, and can be customized according to the workpiece and processing requirements.

★ Product continuous improvement, please contact us if there are any changes to this catalogue parameter. Subject to final confirmation parameters!