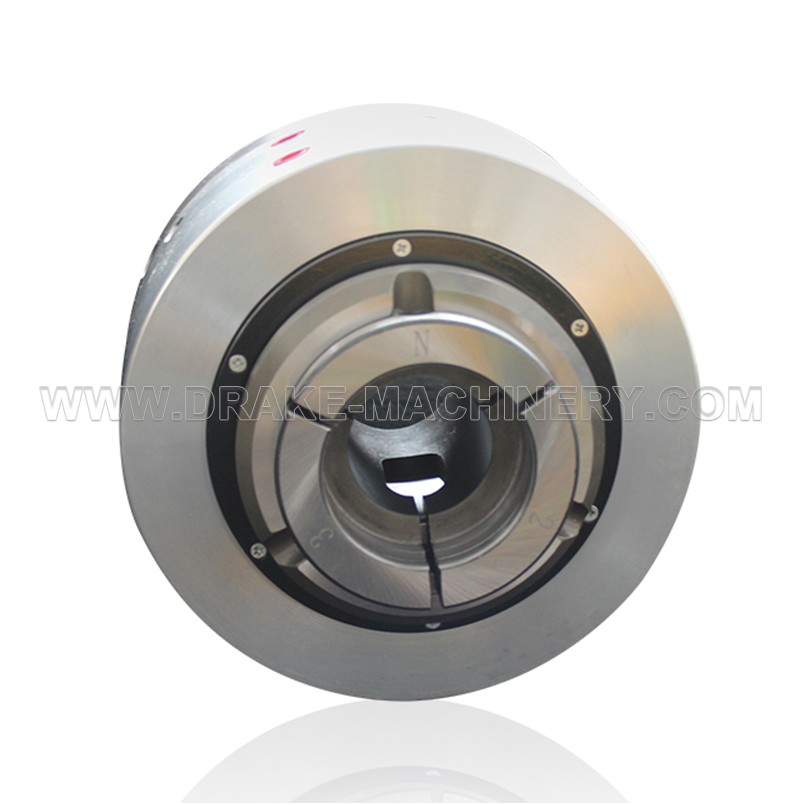

Product Details

Product Features:

Hydraulic built-in machinery, free of hydraulic rotary cylinder.

Clamping accuracy 0.05-0.08mm (10mm from the end face).

The tight dustproof design confirms the applicable life of the protective bearing.

The oil pressure gauge has a strong grip and is easy to handle heavy cutting.

Simple structure, high efficiency and low cost design, aluminum alloy cylinder, light weight and heat dissipation effectively reduce temperature.

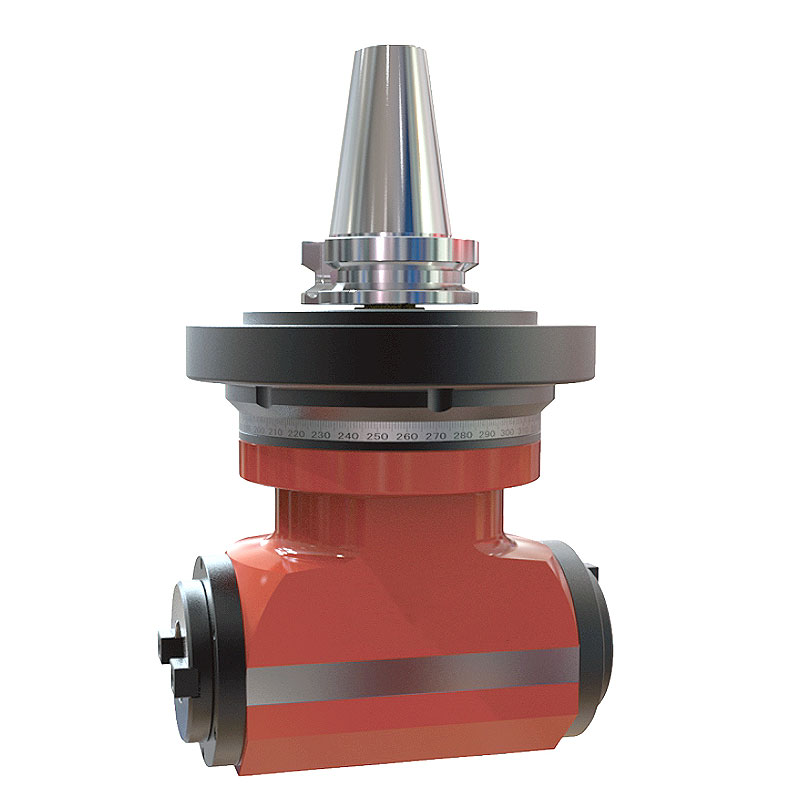

Product Suitability:

Applicable to general precision pipe shaft cutting, inner and outer diameter turning and end face machining.

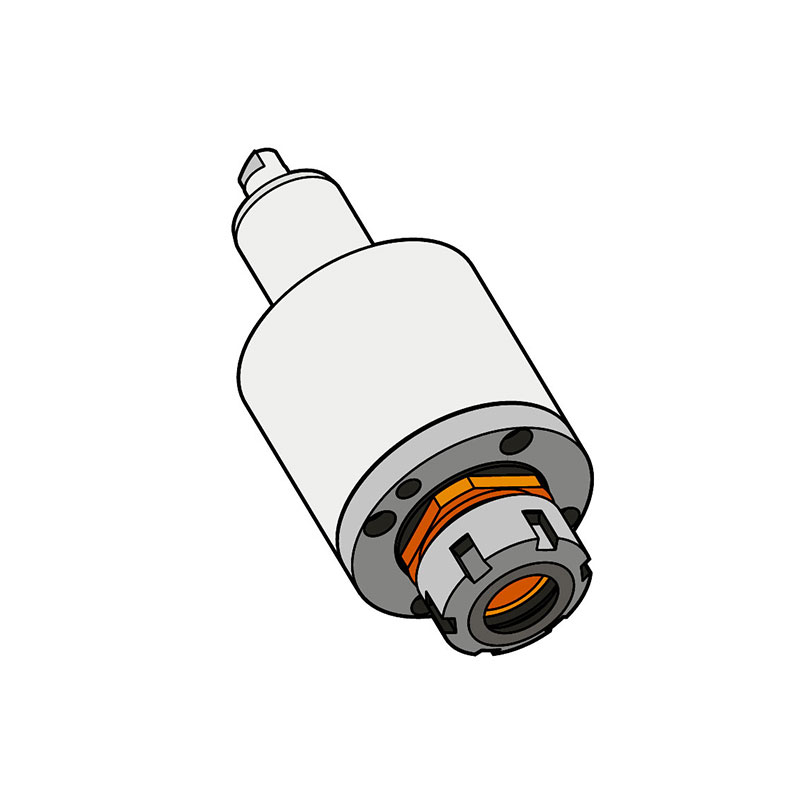

Excessive fatigue, the collet has a probability of breaking and there is a danger of shooting and injury. Always use a protective cover when using it.

Precautions:

Insufficient water resistance, do not use pressurized cutting fluid for a long time.

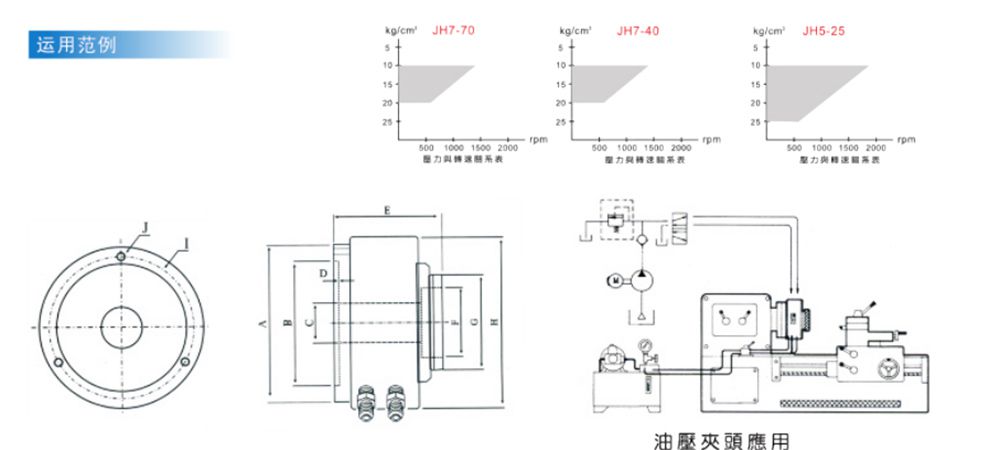

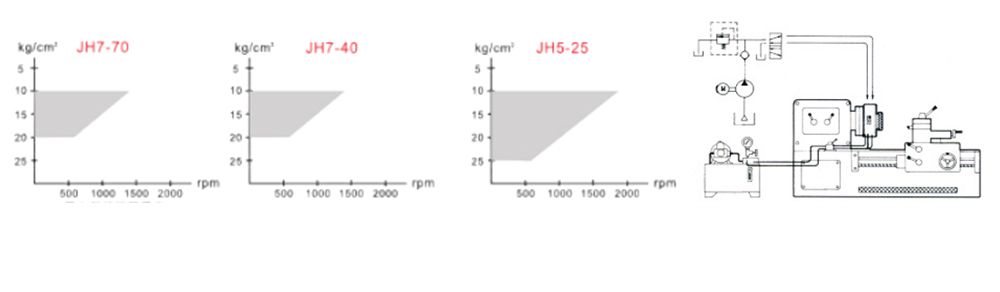

Clearly maintain the pressure and speed limit regulations to ensure bearing life (as shown in the chart below).

Drake is a leading enterprise with 15+ years of factory experience, specializing in machine tool accessories and offering OEM & ODM services. We cooperate with over 60 countries and provide one-stop purchasing solutions for for Power Chuck, Collet Chuck, Turret, Tool Holder, Rotary Cylinder, Laser Chuck, Tool magazine, and more. Our strict adherence to international quality standards and comprehensive product range ensures tailored processing solutions for diverse customer needs.

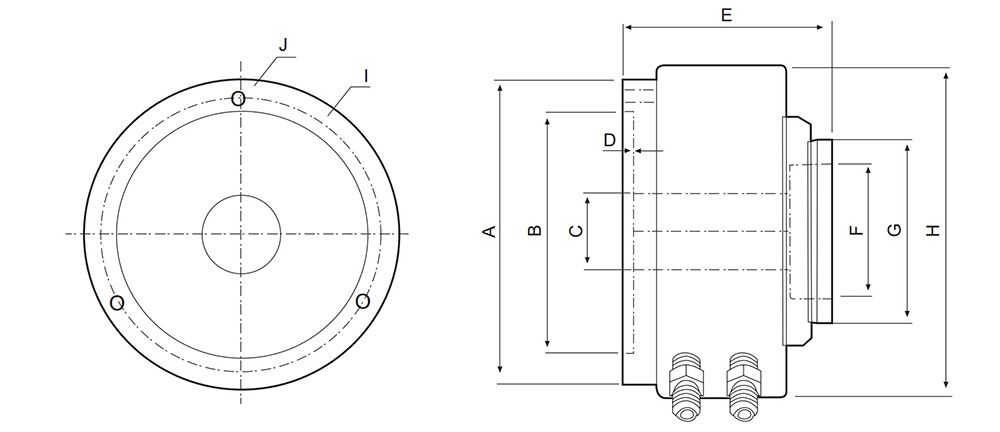

Product Size

Product Parameters

Discover the CNC collet chuck model that suits your requirements from the following parameters. As a leading collet chuck manufacturer, if you have any questions regarding selection, pricing, or technical aspects, please don't hesitate to reach out. Feel free to leave your email along with your inquiries, and our dedicated team will promptly get in touch with you for professional assistance!

| Performance Parameters | ||||||||

| Model/Spec. | Use pressure kg/cm² | Limit speed rpm/min | Clamping torque N.m | Clamping stroke mm | Through-hole aperture | Max.chuck diameter | Matching jaw | Net weight (kg) |

| JH5-25 | 10~25 | 1800 | 30 | 1 | ∮25 | ∮32 | C-25 | 6.9 |

| JH7-40 | 10~20 | 1600 | 40 | 1 | ∮40 | ∮50 | C-40 | 13.6 |

| JH7-70 | 10~20 | 1400 | 40 | 1 | ∮68 | ∮90 | C-70 | 21 |

| JH9-90 | 10~20 | 1100 | 40 | 1 | ∮89 | ∮90 | C-70 | 23 |

| JH9-120 | 10~18 | 900 | 50 | 1 | ∮120 | ∮132 | C-120 | 32 |

| Size Parameters | ||||||||||

| Model/Spec. | A | B | C | D | E | F | G | H | I | J |

| JH5-25 | 135 | 100 | 26 | 4 | 105 | 45 | 68 | 138 | 115 | 3-M8 |

| JH7-40 | 192 | 155 | 46 | 5 | 128 | 65 | 95 | 192 | 172 | 3-M10 |

| JH7-70 | 192 | 155 | 69 | 5 | 141.9 | 105 | 126 | 212 | 172 | 3-M10 |

| JH9-90 | 230 | 190 | 89 | 6 | 150 | 105 | 136 | 232 | 210 | 3-M12 |

| JH9-120 | 230 | 190 | 120 | 6 | 160 | 140 | 168 | 275 | 210 | 3-M12 |

| Note: The clamping torque is measured by clamping a 20mm round bar at a pressure of 20kg/cm2; please observe the pressure display table on the left to ensure the bearing life. | ||||||||||