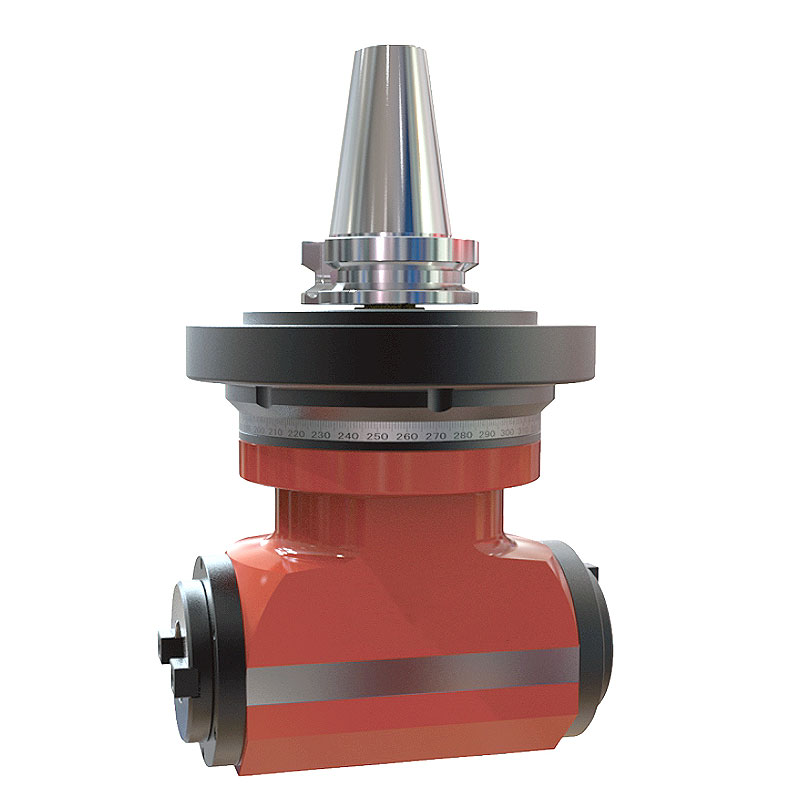

Product Details

Product Features:

It is not fixed for fixed type.

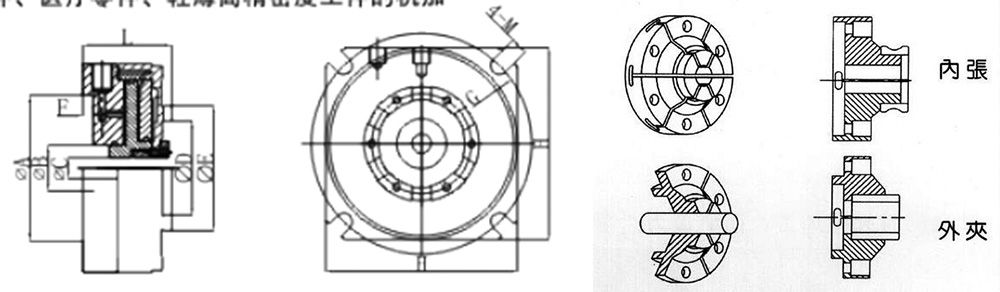

Using diaphragm elastic technology, the precision of heavy soap is less than 3μ, and the clamping precision can reach 2μ.

Permanent precision, high life and high sealing design, waterproof and dustproof.

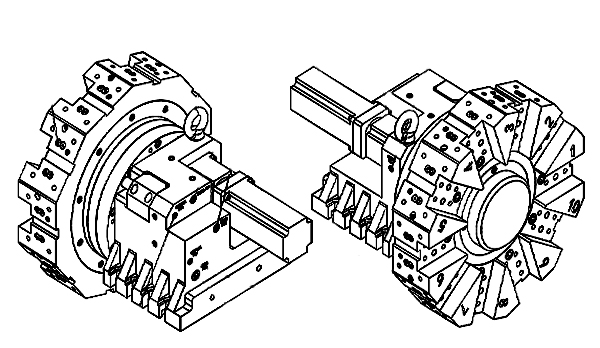

Easily control the concentricity and parallelism of both ends.

Multi-stage size can be processed in several stages to reduce equipment costs.

The single-action grinding machine replaces the CNC multi-stage simultaneous processing.

It needs to be equipped with a rear air cylinder pull rod drive.

The three-point combination clamping force can be finely adjusted.

Product Suitability:

It can be applied to non-standard fixtures such as CNC iron drilling machines, and can be used as multi-station fixtures.

Suitable for microelectronics, optical parts, medical parts, machining of thin and high precision workpieces.

Detection of precision components.

Product Size

Product Parameters

Discover the CNC collet chuck model that suits your requirements from the following parameters. As a leading collet chuck manufacturer, if you have any questions regarding selection, pricing, or technical aspects, please don't hesitate to reach out. Feel free to leave your email along with your inquiries, and our dedicated team will promptly get in touch with you for professional assistance!

| Size Parameters | ||||||||||||||

| Model/Spec. | A | B | C | D | E | F | G | H | L | M | Drive Mode | Working pressure (kg/cm²) | Clamping Stroke (mm) | Matching jaw type |

| JAS4-60 | 70 | 22 | 10 | 45 | 60 | 5 | 120 | 100 | 42.7 | 7 | Air pressure | 2~7 | 0.1 | JD-60 |

| JAS5-70 | 100 | 30 | 15 | 50 | 70 | 5 | 170 | 150 | 49.2 | 9 | Air pressure | 2~7 | 0.3 | JD-70 |

| JAS6-100 | 150 | 50 | 35 | 80 | 100 | 5 | 195 | 177 | 54.3 | 11 | Air pressure | 2~7 | 0.3 | JD-100 |

| JAS8-150 | 180 | 80 | 65 | 120 | 150 | 5 | 245 | 220 | 59.8 | 13 | Air pressure | 2~7 | 0.3 | JD-150 |

| ★The above product data is for reference only, can be changed according to the needs of the workpiece, and can be customized according to the workpiece and processing requirements. ★ Product continuous improvement, please contact us if there are any changes to this catalogue parameter. Subject to final confirmation parameters! | ||||||||||||||