Product Details

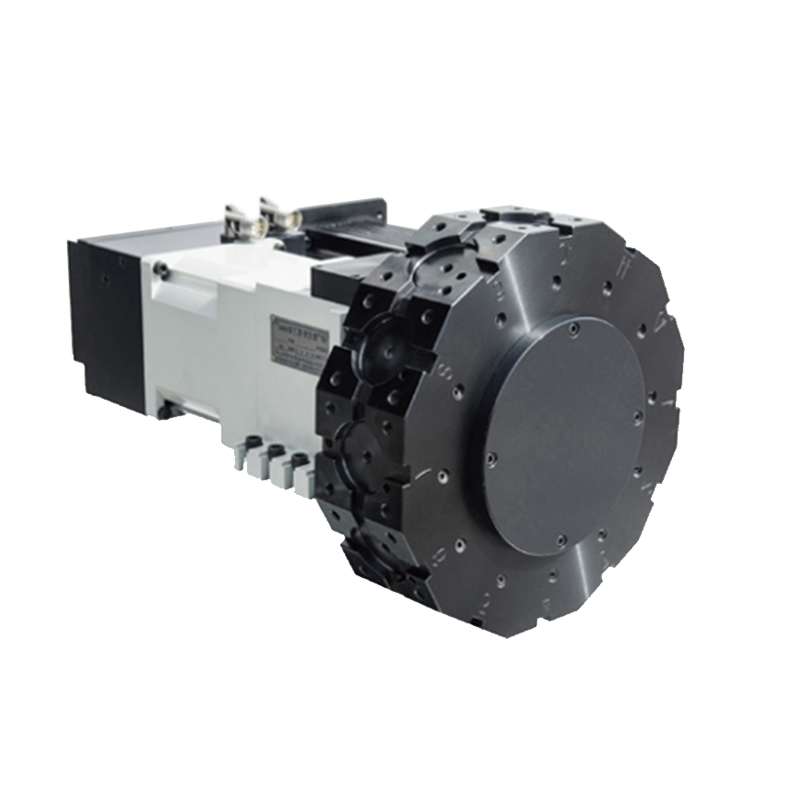

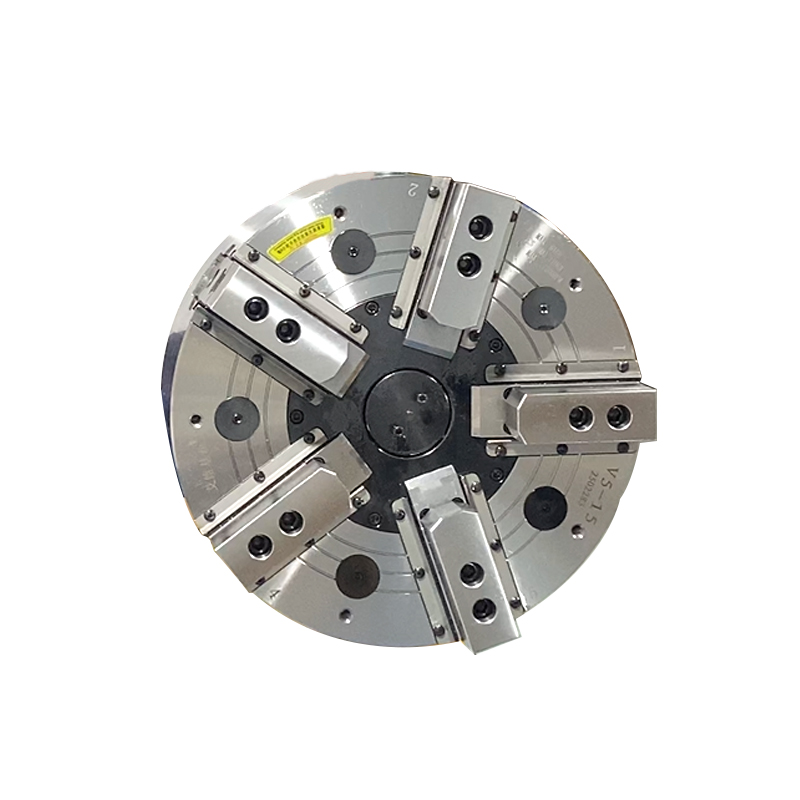

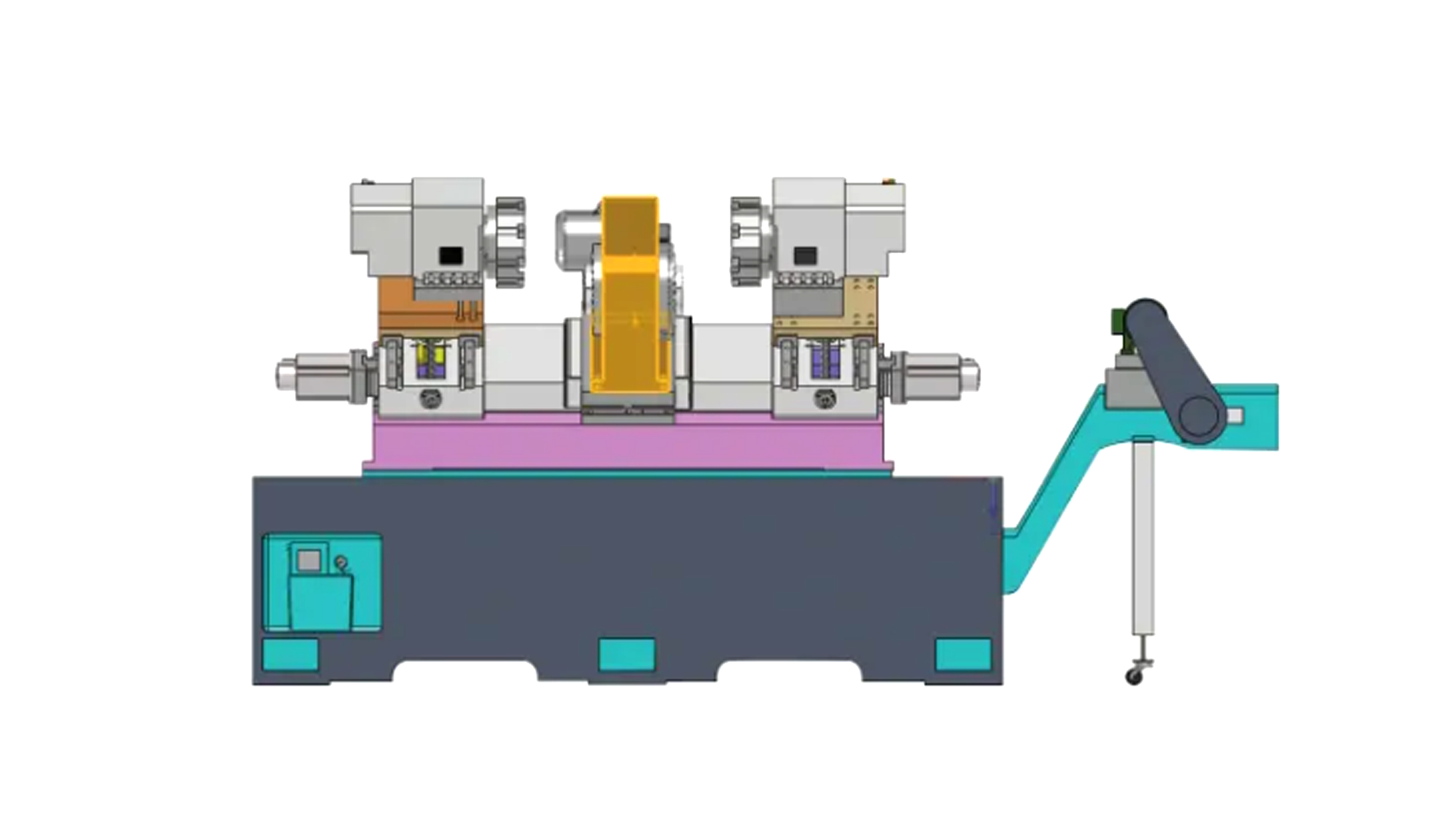

A pneumatic chuck is a mechanical device that can be used to clamp and hold a workpiece for machining. The High Speed Rotary Type Pneumatic Chuck is based on the traditional pneumatic chuck with the function of high speed rotation, which can be used for high speed machining, such as high speed milling, high speed drilling, high speed turning, etc.

The clamping principle of JAB high-speed rotary pneumatic chuck is generally to control the clamping and unclamping of the chuck by air pressure, so it has fast, stable and reliable clamping performance. At the same time, the rotary bearings of the collet are also high-speed bearings, which can withstand the requirements of high rotational speed and high acceleration. With these features, the high-speed rotary pneumatic collet can achieve efficient and high-precision machining needs.

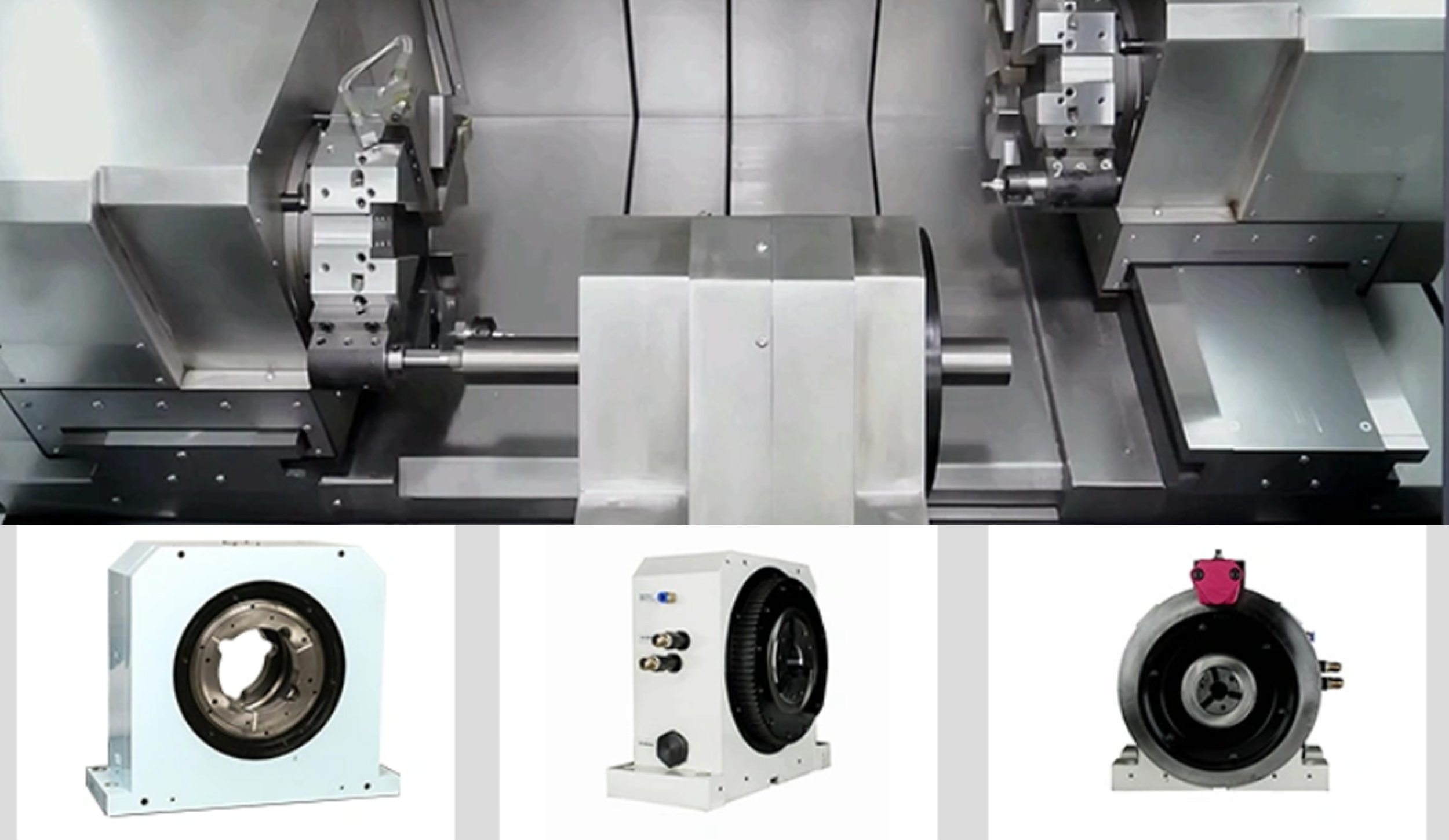

Pneumatic rotary collet chuck is a highly efficient workholding solution that integrates the benefits of a pneumatic collet chuck with rotary functionality. Designed for automated machining processes, a pneumatic rotary chuck ensures precise and rapid clamping, making it ideal for high-speed operations. The rotary pneumatic chuck enhances productivity by providing stable and consistent gripping force, reducing setup time. As a versatile pneumatic chuck, it is widely used in CNC lathes, milling machines, and other precision equipment, offering superior performance and reliability.

Product Features

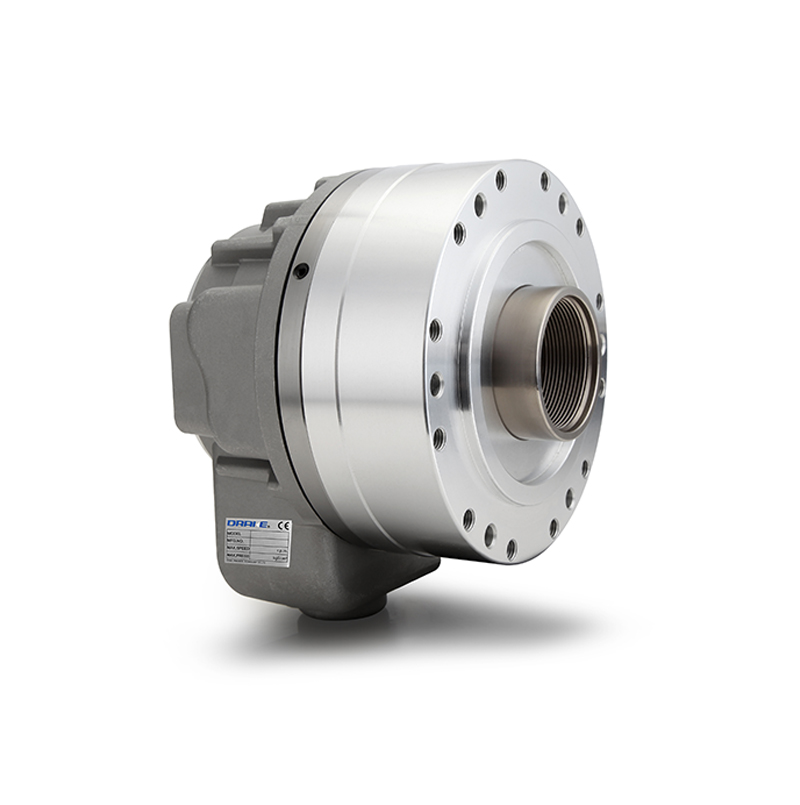

This chuck can be used in either internal or external clamp configurations.

Heat-treated steel integrally formed structure, bearing no load, high speed, long life and low temperature rise.

Two-way power, forced open collet, never jam. When the air source is interrupted, the collet is self-locking.

The direct flange is connected to the main shaft for quick and easy installation. It can be connected to the machine system through a three-point combination valve.

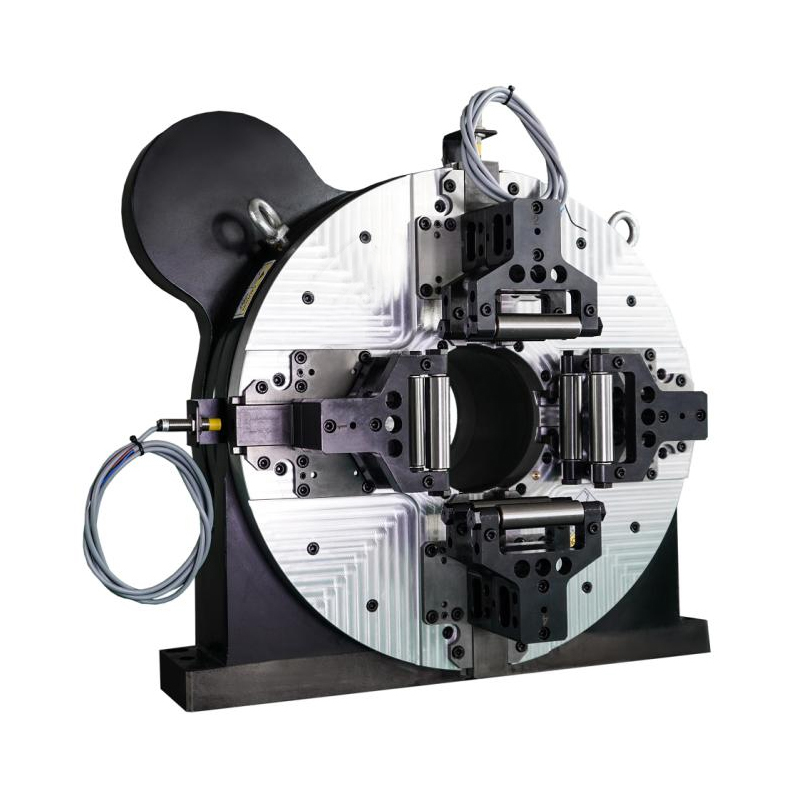

Quickly change the collet to facilitate product replacement, the collet does not retract, and the working length can be controlled normally.

The body accuracy is within 0.01mm.

Product Suitability

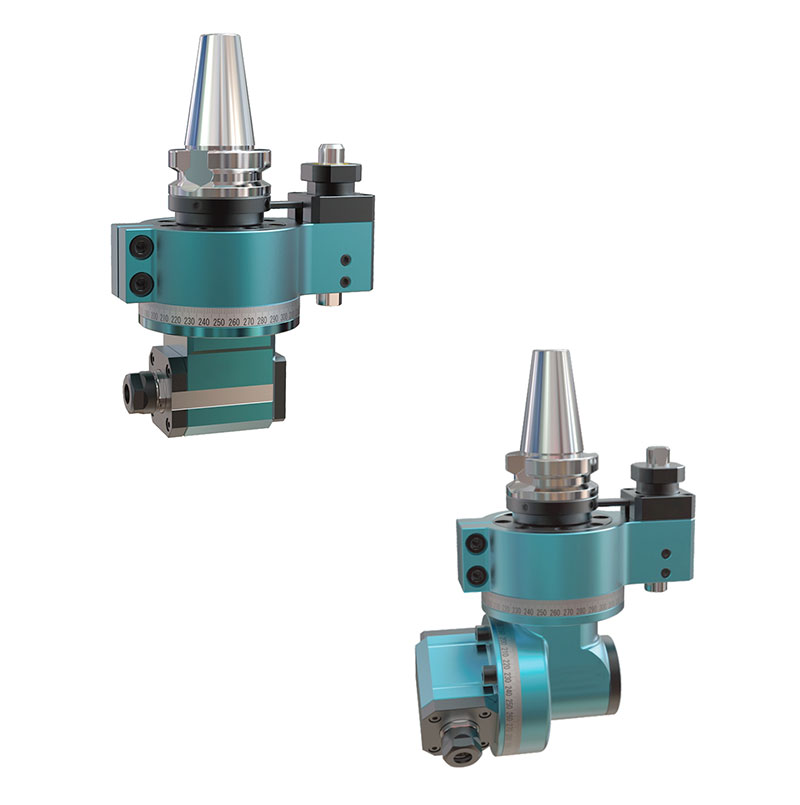

NC lathes, lathes, grinding machines, indexing plates, 4/5 axes.

Turning of batch workpieces.

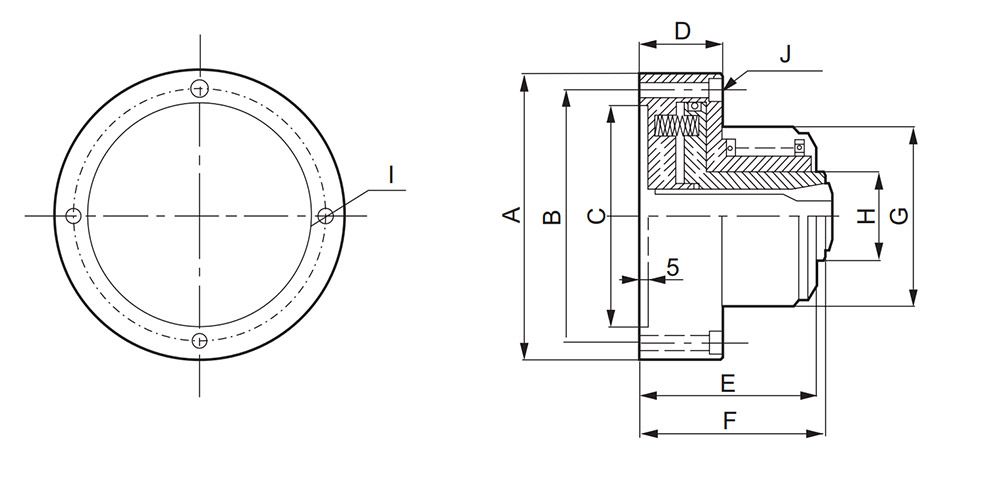

Product Size

Product Parameters

Discover the CNC collet chuck model that suits your requirements from the following parameters. As a leading collet chuck manufacturer, if you have any questions regarding selection, pricing, or technical aspects, please don't hesitate to reach out. Feel free to leave your email along with your inquiries, and our dedicated team will promptly get in touch with you for professional assistance!

| Performance Parameters | ||||||||

| Max. speed (rpm/min) | Piston stroke (mm) | Clamping stroke (mm) | Clamping torque (N.m) | Working pressure (kg/cm²) | Clamping range (mm) | Matching collet | Net weight (kg) | Maximum use pressure |

| 4000 | 4 | 1.52 | 3N.m | 38 | ∮215 | YB-15 | 3.2 | 38kg |

| 4000 | 4 | 1.52 | 15N.m | 38 | ∮525 | YB-25 | 9.5 | 38kg |

| 4000 | 4 | 1.52 | 30N.m | 38 | ∮540 | 16C | 13.5 | 38kg |

| 4000 | 4 | 1.52 | 35N.m | 38 | ∮560 | 20C | 20.35 | 38kg |

| Size Parameters | ||||||||

| A | B | C (H6) | D | E | F | G | H | J |

| ∮100 | ∮84 | ∮70 | 40 | 73 | 80 | ∮71 | ∮30 | 4-M6 |

| ∮166 | ∮147 | ∮130 | 48 | 92 | 104 | ∮104 | ∮52 | 4-M8 |

| ∮187 | ∮168 | ∮150 | 50 | 105 | 118 | ∮168 | ∮72 | 4-M8 |

| ∮220 | ∮203 | ∮170 | 56 | 117 | 126 | ∮168 | ∮100 | 4-M10 |

| Note: The clamping torque is measured by clamping a 20 mm round bar at 6 kg/cm2. | ||||||||

| ★The above product data is for reference only, can be changed according to the needs of the workpiece, and can be customized according to the workpiece and processing requirements. ★ Product continuous improvement, please contact us if there are any changes to this catalogue parameter. Subject to final confirmation parameters! | ||||||||