Product Details

Product Feature:

Hard Jaw for CNC.

High hardness.

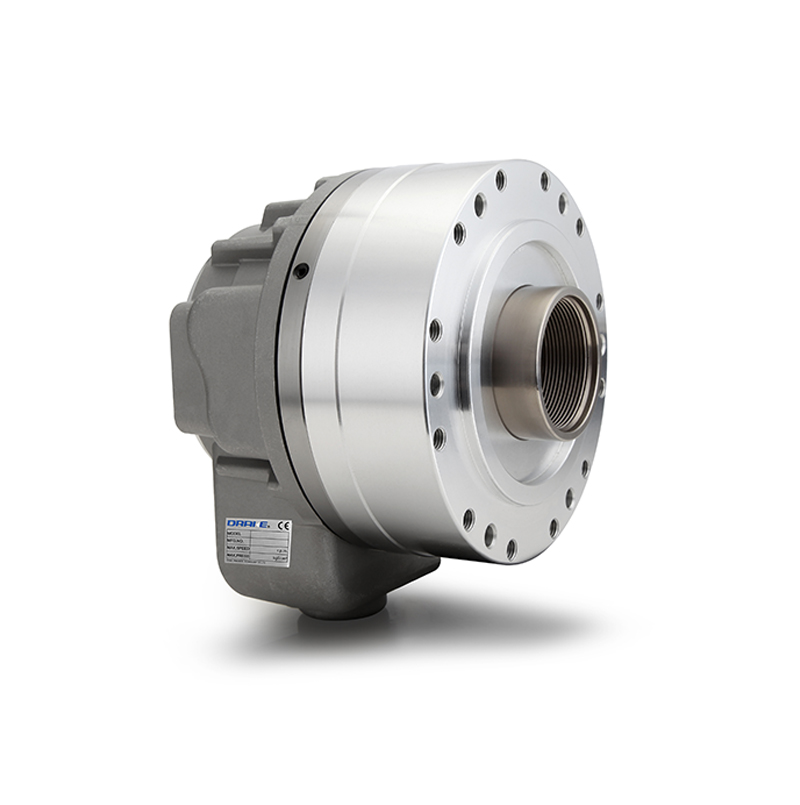

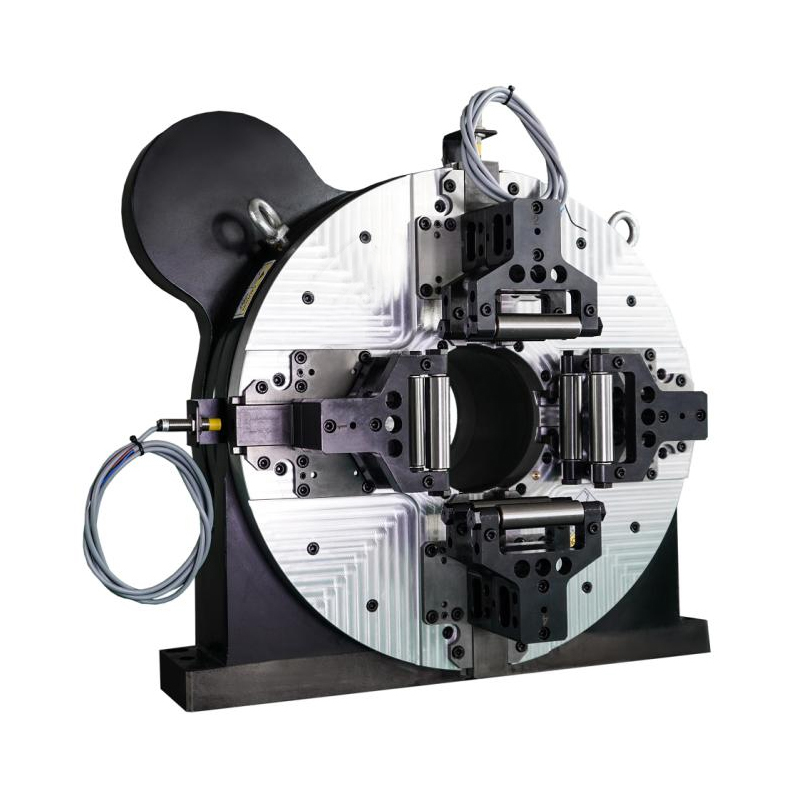

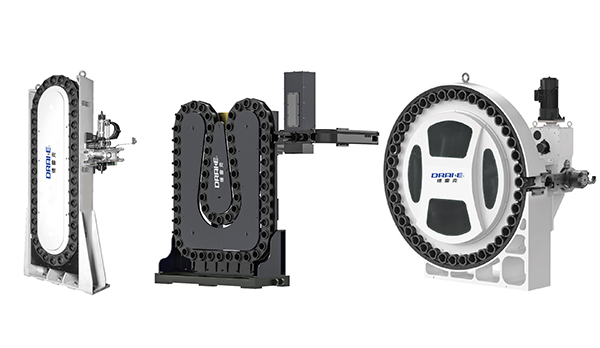

Hard Jaw for a hydraulic power chuck is a critical component in machining and manufacturing processes. These jaws play a crucial role in holding and securing workpieces during various operations, such as turning, milling, and drilling, on CNC machines or manual lathes. Selecting the right hard jaws involves considering factors such as material, design, and operational requirements, ensuring they match the specific needs of the application for optimal performance and safety.

Features of Hard Jaws in Hydraulic Power Chucks

High Precision:

Ensures accurate centering and stable holding, essential for precision machining tasks.

Strong Grip:

Provides a secure hold on the workpiece, reducing the risk of slipping or movement during high-speed operations.

Durability:

Made from materials that can resist wear and deformation, even under significant clamping forces and repeated use.

Interchangeability:

Many hard jaws are designed to be interchangeable, allowing for quick changes between different jaw sets to accommodate various workpiece sizes and shapes.

Customization:

Can be custom-designed to fit specific applications or unique workpiece geometries.

Applications

Turning Operations:

Used in CNC lathes and turning centers to hold cylindrical workpieces for operations like facing, turning, and threading.

Milling:

In some cases, used in milling machines to secure irregularly shaped workpieces or those requiring multi-axis machining.

Drilling and Boring:

Ensure the workpiece remains steady during drilling or boring processes.

Grinding:

Sometimes used in grinding operations where precise and stable holding is required.

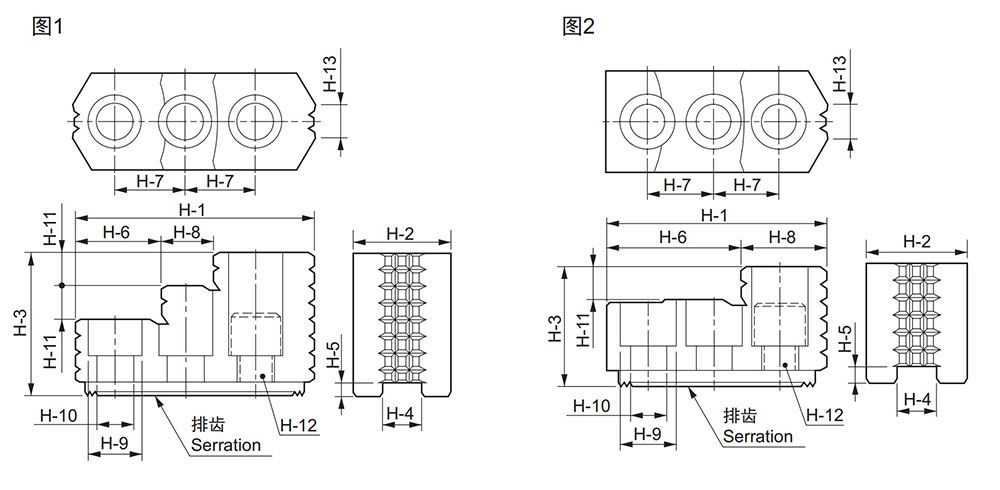

Product Size

Product Parameters

| Size parameters | ||||||||||||||||

| Model/Spec. | H-1 | H-2 | H-3 | H-4 | H-5 | H-6 | H-7 | H-8 | H-9 | H-10 | H-11 | H-12 | H-13 | Serration Pitch | Reference Drawing | 3 jaw weight (kg) |

| HJ05 | 53 | 23 | 27.5 | 10 | 4 | 30.5 | 14 | 22.5 | 13.5 | 8.5 | 10 | M8 | 6 | 1.5×60° | 0.4 | |

| HJ06 | 67 | 31 | 35 | 12 | 5 | 39.5 | 20 | 27.5 | 17 | 11 | 12 | M10 | 11 | 1.5×60° | 1 | |

| HJ08 | 86 | 35 | 51 | 14 | 5 | 31 | 25 | 18 | 19 | 13 | 12 | M12 | 12 | 1.5×60° | 1.9 | |

| HJ10 | 99.5 | 40 | 54 | 16 | 5 | 43 | 30 | 17 | 19 | 13 | 13 | M12 | 15 | 1.5×60° | 2.9 | |

| HJ12 | 103 | 50 | 52 | 21 | 4 | 62.5 | 30 | 40.5 | 25 | 17 | 17 | M16 | 30 | 1.5×60° | 3.5 | |

| HJ12-1 | 103 | 50 | 52 | 18 | 5 | 62.5 | 30 | 40.5 | 22 | 15 | 17 | M14 | 30 | 1.5×60° | 3.6 | |

| HJ15 | 149 | 62 | 86 | 22 | 8 | 63 | 43 | 34 | 32 | 21 | 20 | M20 | 40 | 1.5×60° | 9.6 | |

| HJ15-1 | 149 | 62 | 86 | 25.5 | 5 | 63 | 43 | 34 | 32 | 21 | 20 | M20 | 40 | 1.5×60° | 9.5 | |

| HJ24-1 | 159.5 | 80 | 90 | 25 | 9 | 104.5 | 50 | 55 | 32 | 21 | 40 | M20 | 55 | 3.0×60° | 14.3 | |